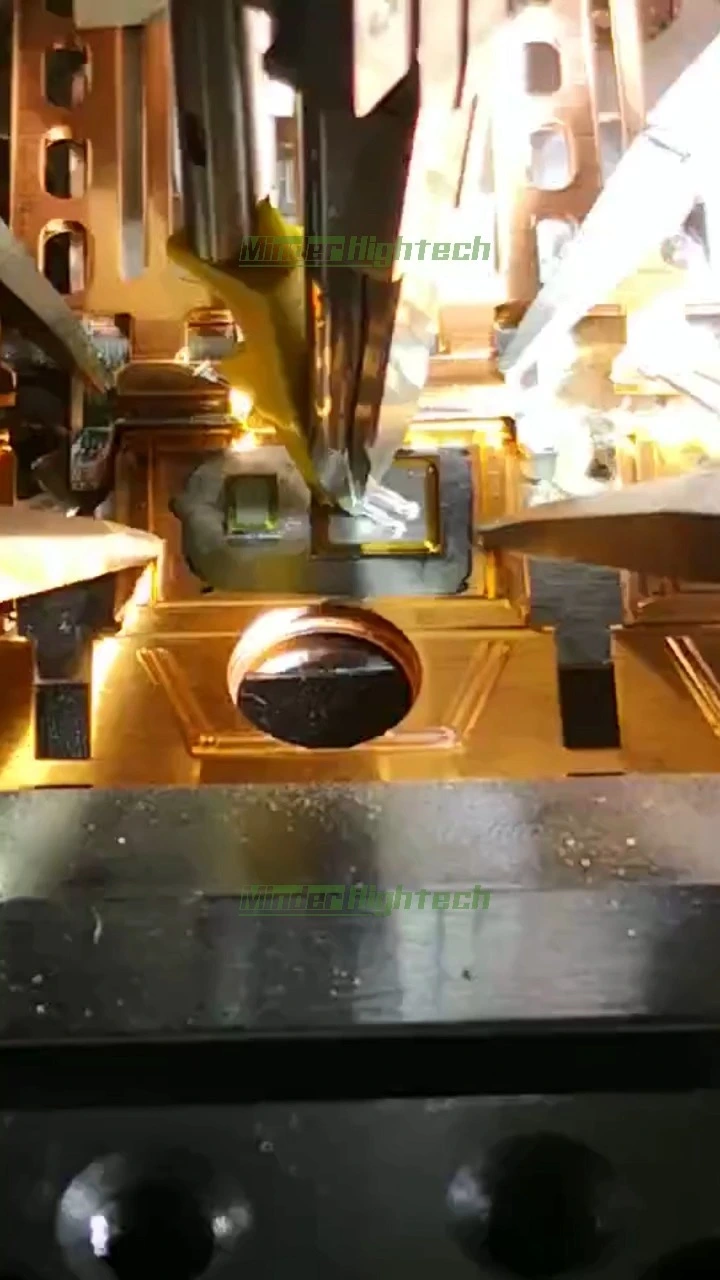

TO220 Wire Bonder

Automatic ultrasonic thick aluminium wire welding pressMDAWB-3721, national first using spin welding head way, adopting digital automatic frequency tracking ultrasonic system, digital control of pressure regulating function, first-class image recognition device, full closed-loop motion control circuit. Really realize China coarse aluminium wire bonding machine fully automated!

MDAWB-3721is mainly used in the TO - 220, TO - 3 p encapsulating large, medium power transistor, SCR, field effect tube, large current fast recovery rectifiers, schottky diode semiconductor power devices in welding lead.

To adopt advanced technology for image recognition and homing technology, realized the automatic and accurate positioning of solder joints.

Strong rich digital ultrasound to ensure the solder joint quality is stable and reliable.

Automatic frequency tracking ultrasonic system and reasonable welding head design to ensure the quality of the solder joints.

Original digital pressure control system to ensure constant output to ensure the consistency of the solder joints.

, blanking agencies use a variety of electronic induction on institutions and get an electric shock control, to ensure the reliability of the automatic up-down material.

The reasonable design of fixture and unique way of feeding to ensure the welding quality and greatly improve the work efficiency.

Precision mechanical transmission mechanism and reliable industrial computer and independent intellectual property rights of software to ensure the precision of the welding position.

Has no weld, pay-off anomalies on a variety of fault alarm stop function, greatly reducing the roa, not at the same time, greatly increased the production. More operable and humanization.

Optional automatic welding line tension testing device, can be more effective is the supervision of the welding line quality.

Adopt computer control, operation interface in Chinese new employee training can operate on its own one day, a month can be skilled

Operation, one person can operate more machine at the same time, greatly improving the work efficiency.

The main technical specifications:

Power supply: 220 vac plus or minus 10%, 50 hz, reliable grounding, maximum rate of about 800 w

Drive source: 4 ~ 6 kg/C ㎡

Ultrasonic power: 0 ~ 30 w, one, two welding automatic switching

Weldable aluminium silk diameter: 125 ~ 500 um (5 ~ 20 mil)

Welding time: 10 ~ 500 ms, 2 channel

Welding stress: 30 ~ 1200 g, 2 channel

Welding speed: about 1300 ~ 1300 / h (TO - 220 double)

Welding Angle: - 90 ~ 90 degrees

The visual system: PR microscope magnification of 0.5 times

PR floodlight: white light, brightness is adjustable

Shape size: 1260 mm * 1860 mm * 760 mm

Weight: 480 kg