RIE Reactive ion etching system

Applied materials:

Passivation layer: SiO2, SiNx

Backsilicon

Adhesive layer: TaN

Through hole: W

Feature:

1. Etching of passivation layer with or without holes;

2. Etching of adhesive layer;

3. Back silicon etching

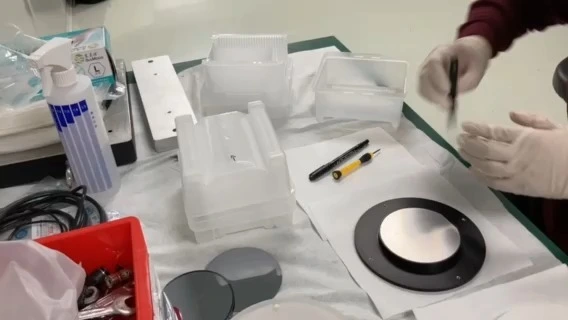

Project configuration and machine structure diagram

Item

MD150-RIE

MD200-RIE

MD200C-RIE

Product size

≤6 inches

≤8 inches

≤8 inches

RF power source

0-300W/500W/1000W Adjustable,automatic matching

Molecular pump

-/620(L/s)/1300(L/s)/Custom

Antiseptic620(L/s)/1300(L/s)/Custom

Foreline pump

Mechanical pump/dry pump

Dry pump

Process pressure

Uncontrolled pressure/0-1Torr controlled pressure

Gas type

H/CH4/O2/N2/Ar/SF6/CF4/

CHF3/C4F8/NF3/Custom

(Up to 9 channels, no corrosive & toxic gas)

H2/CH4/O2/N2/Ar/F6/CF4/ CHF3/C4F8/NF3/Cl2/BCl3/HBr(Up to 9 channels)

Gas range

0~5sccm/50sccm/100sccm/200sccm/300sccm/500sccm/custom

LoadLock

Yes/No

Yes

Sample tem control

10°C~Room tem/-30°C~100°C/Custom

-30°C~100°C /Custom

Back helium cooling

Yes/No

Yes

Process cavity lining

Yes/No

Yes

Cavity wall tem control

No/Roomtem~60/120°C

Room tem-60/120°C

Control System

Auto/custom

Etching material

Silicon-based:Si/SiO2/SiNx···

IV-IV: SiC

Magnetic materials/alloy materials

Metallic material: Ni/Cr/Al/Au.....

Organic material: PR/PMMA/HDMS/Organic

film......

Silicon-based: Si/SiO2/SiNx......

III-V(注3): InP/GaAs/GaN......

IV-IV: SiC

II-VI (注3): CdTe......

Magnetic materials/alloy materials

Metallic material: Ni/Cr/A1/Au......

Organic material: PR/PMMA/HDMS /organic film...

Process result

Silicon-based material etching

Silicon-based materials, nano-imprint patterns, array

patterns and lens pattern etching

InP normal temperature etching

Pattern etching of InP based devices used in optical communication, including waveguide structure, resonant cavity structure ridge structure etc

SiC material etching

Suitable for microwave devices, power devices, etc

Physical sputtering, etching Organic materiale tching

|

It is applied to the etching of difficult to etch materials such as some metals (such as Ni / Cr) and ceramics, and the patternede tching of materials is realized by physical bombardment. |

It is used for etching and removal of organic compounds such as photoresist (PR)/ PMMA / HDMS / polymer |

Cermet film material (Au/Ni/Cr/Al2O3)

Display of failure analysis results:

Specification:

1. Prevent chips from flying

2. Minimum node that can be processed: 14nm;

3. SiO2/SiNx etching rate: 50~150 nm/min;

4. Etched surface roughness:<1 nm;

5. Support passivation layer, adhesion layer and back silicon etching;

6. Selection ratio of Cu/Al:>50

7. All-in-one machine LxWxH: 1300mmX750mmX950mm

8. Support one-click execution