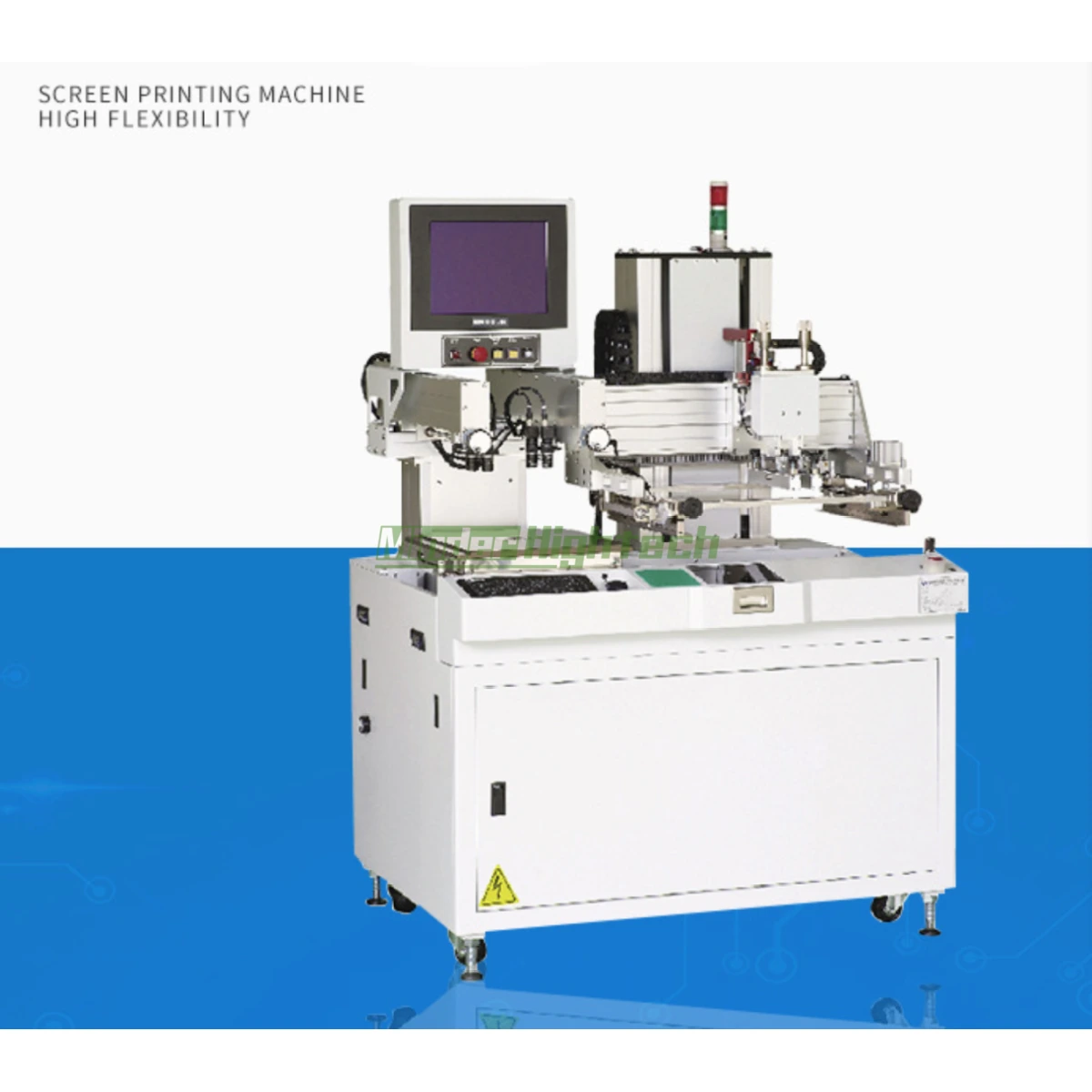

MD-WY-216T CCD Screen Printing machine / Screen Printer

Charactor:

The substrate is in the feeding station. After the initial positioning, the vision system drives the alignment platform to accurately position, and then the printing shift table on the shuttle mechanism of the treadmill sends the substrate to the printing platform, and then prints on the printing platform. After the printing is completed, the discharging shift table takes out the printed substrate from the printing platform and transports it to the discharging station. At the same time, the printing shift table sends the substrate to the printing platform.

Main performance characteristics of automatic CCD visual alignment screen printing machine

1. PLC program control.

2. Automatic feeding, CCD automatic alignment, automatic discharging after printing.

3. The printing head lifting adopts Japanese Panasonic servo motor to drive the ball screw to

realize the position switching, and the speed is stable and adjustable.

4. Japan Panasonic servo motor drives printing, photoelectric control stroke, independent

adjustment.

5. Printing adopts independent driving source, coordinated movement, stable and adjustable

speed.

6. There are three printing modes: manual/semi-automatic/full-automatic, and it can print up

to 10 sheets per minute.

7. The treadmill is driven by a new technology-linear motor, with a repeatable positioning

accuracy of 0.01mm.

8. The whole machine is equipped with safety protection devices to ensure the safety of

workers.

9. The squeegee pressure is controlled by Airtac precision pressure regulating valve, the angle

and balance can be adjusted, and it is equipped with a scale display.

10. The CCD lens is adjusted by a precision displacement stage, with accurate positioning and

simple operation.

11. The screen frame is mechanically locked, which is convenient and firm.

Main technical parameters of automatic CCD visual alignment screen printing machine

Printing platform size 720×600 mm

Maximum printing area 500×500 mm

Minimum printing area 350×350 mm

Printing thickness 0.2~3 mm

Suction area 480×480 mm

Treadmill speed 100~2000mm/s

Platform height 900+30mm

Platform displacement method UVW linkage

CCD resolution accuracy ≤0.0035mm

CCD to platform distance 150mm

Counterpoint time ≤2s

Overprint accuracy ±0.025mm

Maximum frame size 1000×1000 mm

Minimum frame size 600×600 mm

Net frame height 25~50mm

Washing height 300mm

Squeegee pressure 0.4~4 Kgf/cm²

Scraper inclination 0°~45°

Scratch/return ink speed 50~650mm/s

Repeatability of printing head lifting ±0.03mm

Maximum capacity 720P/h

Applicable power supply 220V/380V,50HZ/60HZ

Applicable air source 0.5~0.7Mpa

Power consumption 4.5KW

Air consumption 84 L/min

Machine size 3000x1500x1800mm

Squeegee pressure ≈950kg