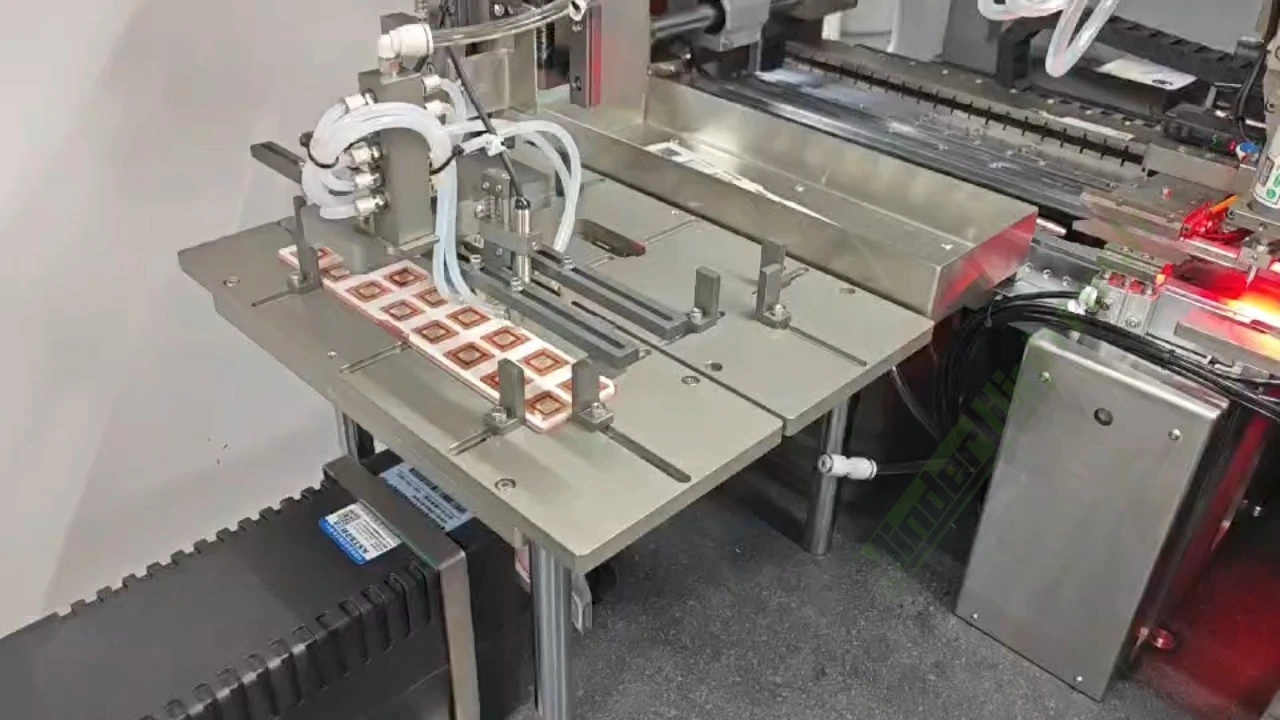

MDDB-LA838 Die attach

|

Using Windows 7 operating system |

|

|

21.5 inch LCD display |

|

|

4. Visual system: |

Accurate image recognition and positioning system |

|

Z-direction travel of ejector: |

4mm |

|

Bonding pressure: |

Surface absorption 20g-200g(optional 500g) |

|

Bonding X/Y/Z: |

Linear motor reciprocating |

|

Bonding angle: |

Multi-angle solidification |

|

Dispensing system: |

Independent double point adhesive system |

|

Wafer platform: |

Equipped with automatic wafer expanding system and mapping function |

|

Track: |

Adjust the width according to the actual size of the frame, and the bottom plate has vacuum adsorption, and the upper surface has a downward pressure type fixture |

|

Loading and unloading system: |

There are two options for feeding: suction feeding and box feeding; Blanking and receiving with material box |

|

Motor control: |

High precision AC servo drive motor, linear motor system |

|

Crop specification |

|

|

Work cycle: |

14K/H(The actual production capacity is determined according to the leadframe) |

|

XY positioning accuracy: |

±1mil |

|

Die deflection angle: |

±3° |

|

Production Product Specifications |

|

|

Leadframe: |

Width 35MM~100mm |

|

Die size: |

5mil*5mil~120mil*120mil |

|

Wafer Ring Size: |

ø14″(OD400mm ID350mm) |

|

Electrical specifications |

|

|

Power Supply: |

220V±10V,50HZ,1.3KW |

|

Air source ( positive pressure): |

0.4~0.6Mpa |

|

Air source (negative pressure): |

-85~-100Kpa |

|

Appearance specification |

|

|

Volume (L * W * H): |

1350mm*1400mm*1750mm |

|

Weight: |

1100Kg |

|

work environment |

|

|

ambient humidity: |

40%-70% |

|

Ambient temperature: |

22℃-26℃ |

|

Space: |

It is recommended to reserve 50-100cm for the weekly maintenance of the equipment to facilitate maintenance |