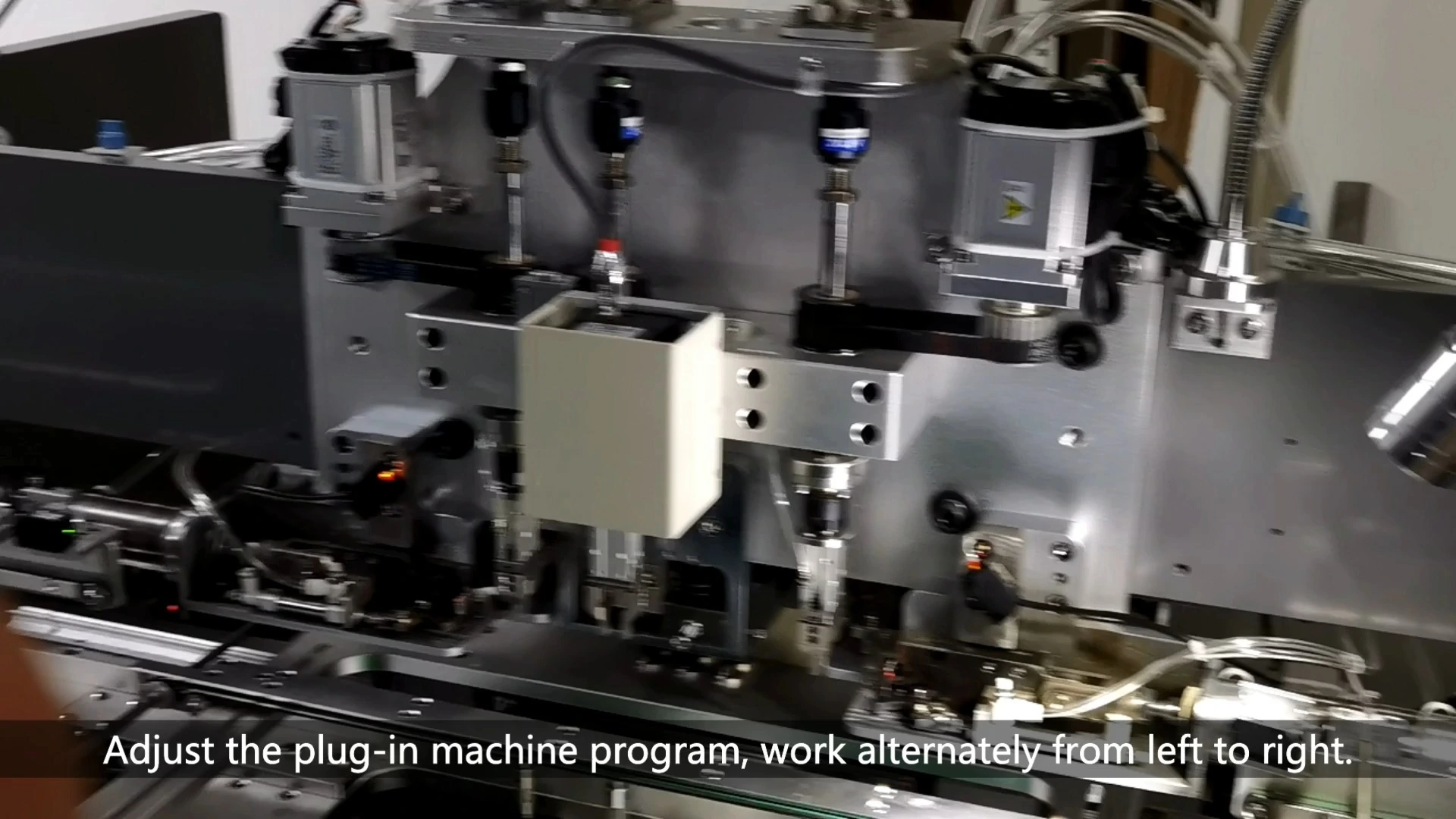

MD8400 Connector Plug-in machine / Connector Terminal Insertion Machine

Introduction:

Connector component plug-in machine automatically inserts various non-standard braided horizontal components into the PCB according to the set program. It has the fixed tail function and the detection function to achieve high speed, high precision and high stable insertion effect

Operation system:

production data, management data, device parameters, editing program, all I/O signal diagnosis in Windows environment can be completed on the host, the interface is user-friendly, the device profile is efficient, and the operation is simple.

Visual System:

The industrial-specific high-definition camera and the self-developed vision correction software form a vision system. The deviation between the PCB hole position and the programmed input coordinates can be quickly and automatically calibrated to match all the coordinates with the actual PCB hole position, ensuring the plug-in accuracy and greatly improving the programming efficiency.

Plug in speed:

0.45 seconds / piece, equipped with Panasonic AC servo drive, high speed, low noise, smooth motion

Missing parts detection:When the missing part is inserted, the missing part detection can be realized and a supplementary insertion function can be provided.

Important Parts Brand:

01.Servo motor adopts Japanese Panasonic brand

02.Sending board, feeder system motor adopts Oriental brand

03.Pneumatic components adopt Taiwan Airtic brand

04.The lead screw adopts the Japanese THK brand

05.Camera system uses CGimagetech brand (5 million pixels)

06.Photoelectric sensor adopts SUNX brand of Japan

07.The main parts are made of Japanese mold steel