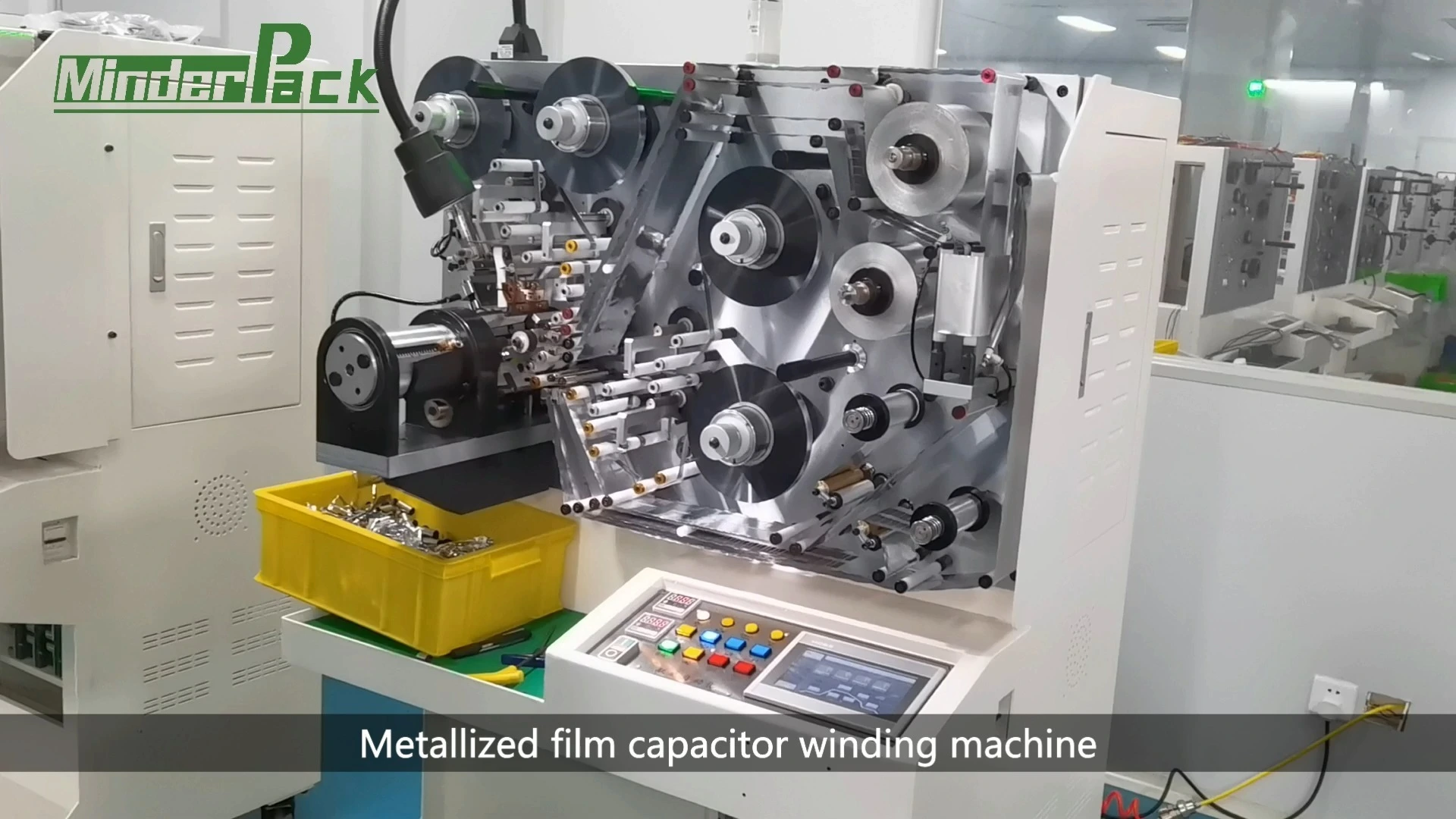

MD-E Capacitor Metallized film Winding Machine

Characteristics

1. This machine adopts Siemens enhanced Smart PLC and touch screen control, with capacity calculation, parameter storage, data reading functions, to achieve intelligent operation.

2. Internal and external washing can adjust, shorten the length, save materials and improve efficiency.

3. Air guide mechanism can be added according to product requirements to effectively prevent material deviation and improve quality.

4. The machine can choose to add explosion-proof film cleaning mecha-nism according to product requirements.

5. Integral frame improves strength and seismic resistance, chassis can put materials, while ensuring the accuracy and durability of equipment.

6. Integral main winding mechanism, 5 positioning pins of body base are installed on horizontal base plate in the same position, which ensures the coaxiality of the winding shaft when winding, improves product accuracy and reduces noise.

7. Translational material stagger adjusting mechanism ensures the vertical accuracy of the tray after moving, and the tray inside and outside can move arbitrarily, so the operation is convenient and convenient.

|

Project |

E24L |

E30L |

E40L |

E60L |

E80L/XL |

|

Width of double roll material(mm) |

4.5-12 |

6-16 |

9-22 |

14-30 |

19-40 |

|

Width of single roll material (optional)(mm) |

/ |

80 |

|||

|

Thickness of Metal Film Material(μm) |

1.2-10 |

2.5-10 |

2.5-10 |

3-10 |

3.5-10 |

|

Inner/Outer Diameter of Metal Film(mm) |

75/180 |

75/210 |

75/240 |

75/260 |

|

|

Aluminum foil thickness(μm) |

15-20 |

||||

|

Aluminum foil width(mm) |

30 |

35 |

50 |

70 |

90 |

|

Inner/Outer Diameter of Aluminum Foil(mm) |

40/160 |

||||

|

Standard mandrels diameter(mm) |

1.5,2,2.5,3 |

2,2.5,3,4 |

2.5,3,4,5 |

3,4,5,6 |

4,5,6,8 |

|

The range of mandrels(mm) |

1.2-5 |

2-5 |

2.5-6 |

3-8 |

4-10/4-15 |

|

Maximum diameter of elements(mm) |

28 |

45 |

|||

|

Material hanging shaft(pc) |

4 |

||||

|

Maximum speed of main volume(rpm) |

10000 |

9000 |

7500 |

||

|

Tension range(g) |

20-120 |

20-120 |

30-180 |

50-400 |

50-600 |

|

Pressure range(g) |

0-480 |

0-960 |

|||