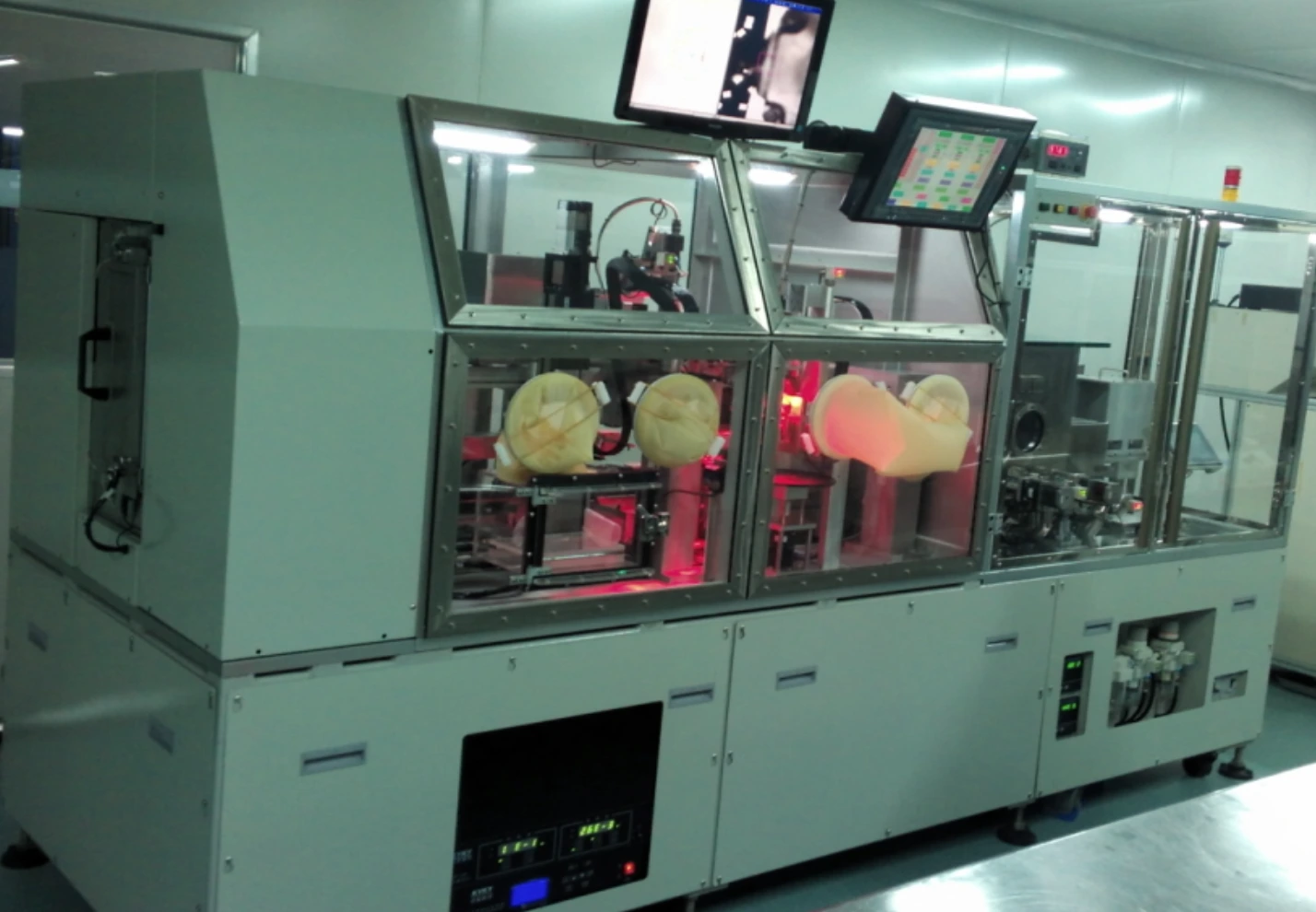

Full automatic seam sealer

Full automatic seam sealing welding machine is mainly used for SMD quartz patch crystal automatic spot welding and automatic roll welding production process.This machine is suitable for series 7 and 2. It can be used for a wide range of products. This machine is a high degree of automation, high vacuum seam welding, make product welding effect is very good, after welding of the resistance value of achieve ideal result, the speed and length of the roll welding can be adjusted freely, seam welding speed for spot welding and seam welding station location can change at any time, it's a good help for repair welding, after the power is back on electricity can then go ahead, the machine USES 260000 color touch screen operation, the operating interface is more good-looking, Chinese interface makes operation is very simple, easy operation, efficiency is very high, up to 4000 PCS per hour, with small volume (short compared with foreign machine 0.8 meters, Narrow 0.4 m), high efficiency, easy to train operators operating characteristics. 32 pieces of packaging board can be placed at a time, one person can see 4 machines, so that your product labor cost greatly reduced, the price is cheap, the operation is simple, easy to maintain, the manufacturer follow-up service is good.

Action description:

① Discharge fine crystal into return furnace (up to 16 layers).

② After the completion of the annealing furnace, the storage folder will be automatically collected (At this time, continue to feed the annealing furnace on the 16th floor).

③ After the storage rack is completed, the spot welding is automatically carried out to the 1 welding points.

④ When welding 1 finishes spot welding 50 % of a plate, it will automatically arrive at spot welding 2.

⑤ After welding 2 spot welding is completed, it will automatically reach the strength of roll welding( welding 3 ).

⑥ After welding 3 is completed, automatic access to Front pre-suction vacuum chamber.

⑦ After completing the Front pre-suction vacuum chamber, automatic welding 4 roll welding short side

⑧ After finishing soldering 4, automatic access to rear pre-extraction vacuum chamber.

⑨ Material receiving rack ( 16th floor )

Features of this machine:

① The whole machine is advanced in design, beautiful in appearance, reasonable in structure, low in power consumption and convenient to maintain and operate

② The software and hardware of the main transmission system adopt the modular machine and control drive device manufactured by Japanese company, which has high movement precision, accurate and reliable positioning, and maintenance-free function, making subsequent maintenance very simple.

③ It has the functions of automatically correcting and positioning spot welding and automatically feeding spot welding cover sheets.

④ It has the function of high vacuum adjustment and display, and high vacuum seam welding can upgrade the product grade.

⑤ It has the function of adjusting seam welding speed.

⑥ It has the feedback function of poor seam welding.

⑦ it has the function of spot welding and sewing welder position selection.

⑧ The operation interface uses a 260,000 - color touch display, which makes the operation easier and the interface more beautiful. the Chinese interface on the operation and adjustment is quite simple and intuitive, and the alarm information is simple and clear. after the alarm, the interface displays the corresponding processing steps, making the operator simpler and easier.

⑨ Applicable to SMD products such as 7 series, 5 series, 3 series and 2 series, and also suitable for welding and packaging of resonator, oscillator, sound meter and other products.

Technical indicators:

① Product specifications: SMD Shi Ying crystal, resonator, oscillator, sound meter

② Working efficiency: 4000 PCs / hour

③ Air source:≧0.3Mpa

④ Power supply:380V±10% 50/60Hz 60A

⑤ External dimensions: 3700× 1400× 1800

⑥ Weight: about 2800 kg