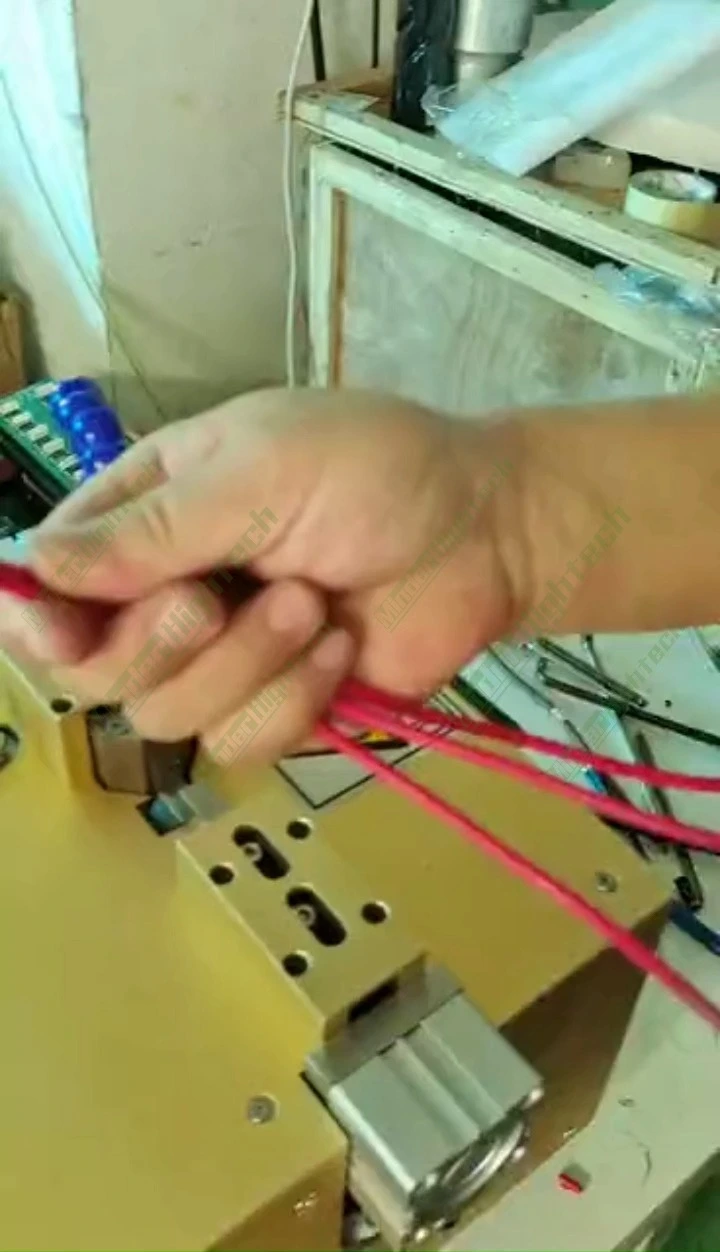

Ultrasonic Metal Welder Wire Splicing Machine

Principle:

The principle of ultrasonic metal welding is a special method of using the mechanical vibration energy of ultrasonic frequency to connect the same or different metals. When metal is welded by ultrasonic, it neither delivers current to the workpiece nor applies high temperature heat source to the workpiece, just only under static pressure, the wire frame vibration energy is transformed into friction work, deformation energy and limited temperature rise between the workpieces. The metallurgical bonding between the joints is a solid state welding that is realized without the base material melting. Therefore, it effectively overcomes the spatter and oxidation caused by resistance welding. Ultrasonic metal welding machine can perform single-point welding, multi-point welding and short strip welding on thin wire or sheet materials of non-ferrous metals such as copper, silver, aluminum, and nickel. It can be widely used in the welding of SCR leads , fuse pieces , electrical leads , lithium battery pole pieces , and tabs.

Advantages of ultrasonic metal welding:

- The welding material does not melt, and the metal is not fragile

- The conductivity is good after welding, and the resistivity is extremely low or almost zero.

- Low requirements on the surface of the weld metal, both oxidation and electroplating can be welded.

- The soldering time is short, without any flux, gas, or solder.

- Welding without sparks, environmental protection and safety.

Materials and Applications:

- Ni-MH batteries, nickel-metal hydride batteries, nickel mesh and nickel sheets welding and nickel sheets welding.

- Lithium battery and polymer battery copper foil and nickel sheet welding, and aluminum foil and aluminum sheet welding.

- Wires welding to each other, and the wires weld to one or multiple wires.

- Wires weld with various electronic components, contacts and connectors.

- Welding of large heat sinks, heat exchange fins and honeycomb

|

Model |

MD-XSBW2030 |

MD-XSBW2040 |

MD-XSBW2050 |

||

|

Ultrasonic frequency |

20KHz |

||||

|

Input |

AC220V/50Hz |

||||

|

Ultrasonic power |

3000W |

4000w |

5000W |

||

|

Air pressue |

0.4MPa~0.6MPa |

||||

|

Control |

time/energy/ |

||||

|

Stroke |

30mm |

||||

|

Head |

550*350*350mm |

550*350*350mm |

550*350*350mm |

||

|

Generator |

450*435*140mm |

||||

|

Weight |

65kg |

65kg |

65kg |

||