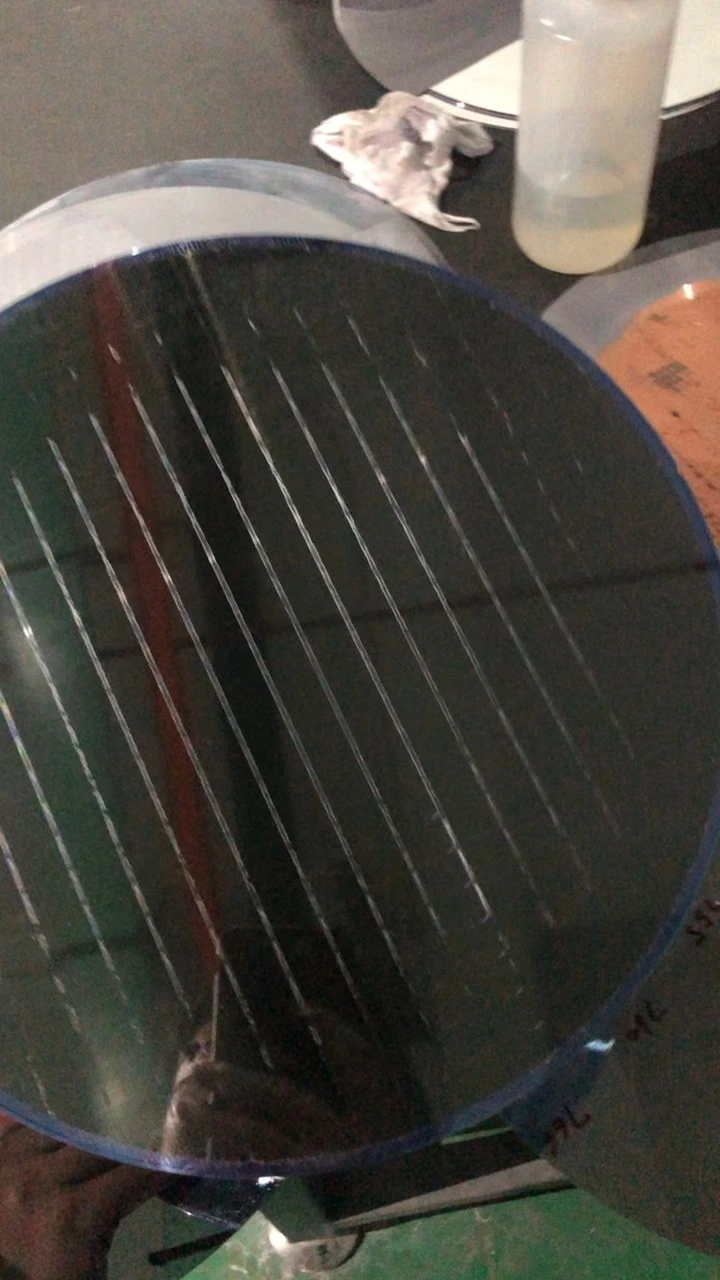

Semi Auto Wafer Thinning Grinder

High precision grinding machine equipment principle:

1. This series of transverse thinning grinding machine is a fully automatic precision grinding equipment. The workpiece is rotated in the opposite direction by the vacuum suction cup or electromagnetic suction cup, and the grinding wheel swings back and forth. The grinding resistance is small, the workpiece will not be damaged, and the grinding efficiency is high.

2. The equipment can automatically set the tool, actually detect the grinding torque, and automatically adjust the workpiece grinding speed, so as to prevent the workpiece from deformation and damage due to excessive pressure in the grinding process, and automatically compensate the grinding wheel wear thickness.

Application:

| Single Plate Lapping & Polishing |

Metal And Alloy Ceramic Oxide Carbide Glass Plastic Nature Stone |

Sealing | valve and sealing ring(liquid, oil, gas) |

| Semiconductor | LED substrate(Al2O3, Si, SiC) wafer substrate(Si, SiC, Ge, Ge-Si, GaN, GaAs, GaAsAl, GaAsP, InSb, ZnO, AlN) |

||

| Plastic | PE, E/VAC, SBS, SBR, NBR, SR, BR, PR | ||

| Phone Frame(flat) | back plate | ||

| PCB | adhesive, coating, circuit | ||

| Optics(flat) | optical lens, optical reflector, scintillator cube, holographic glass, HUD glass, screen glass | ||

| Radar | oxide coating plate | ||

| Gemstone | jade, sapphire, agate, etc. | ||

| Others | graphite block, gauge block, micrometer gauge, diamond, friction plate, knife, bearing, metal components, and any other precise hardware. | ||

| *NOTE: lapping can only remove slight thickness of workpiece. If need ultra thinning (≤100μm), thinner machine are needed. | |||

SAMPLE