Wholesale Ultrasonic Wire Welder Minder Machine Brand

Product details of the ultrasonic wire welder

Product Overview

These Minder Machine ultrasonic wire welder are designed and developed in line with industry norms and standards. The most important difference between this product and other products is the long-term service life. Guangzhou Minder-Hightech Co.,ltd is a company with mature sales network who makes the shopping experience more convenient.

Product Information

Compared with similar products, Minder Machine's ultrasonic wire welder has the following advantages.

Product Introduction

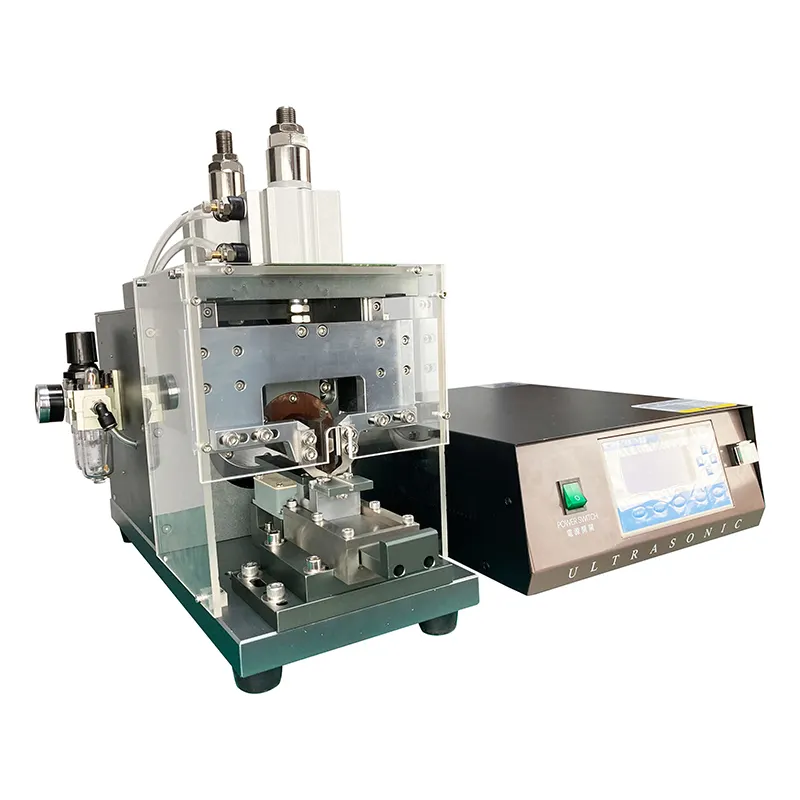

--- Ultrasonic Terminal Welding MachineThe principle of ultrasonic metal welding is a special method of using the mechanical vibration energy of ultrasonic frequency to connect the same or different metals. When metal is welded by ultrasonic, it neither delivers current to the workpiece nor applies high temperature heat source to the workpiece, just only under static pressure, the wire frame vibration energy is transformed into friction work, deformation energy and limited temperature rise between the workpieces. The metallurgical bonding between the joints is a solid state welding that is realized without the base material melting. Therefore, it effectively overcomes the spatter and oxidation caused by resistance welding. Ultrasonic metal welding machine can perform single-point welding, multi-point welding and short strip welding on thin wire or sheet materials of non-ferrous metals such as copper, silver, aluminum, and nickel. It can be widely used in the welding of SCR leads, fuse pieces, electrical leads, lithium battery pole pieces, and tabs

Related Parameters

|

Model |

MD-T2030 |

MD-T2040 |

MD-T2050 |

MD-T2080 |

|

Ultrasonic frequency |

20KHz |

|||

|

Input |

AC220V/50Hz |

|||

|

Ultrasonic power |

3000W |

4000W |

5000W |

8000W |

|

Air pressue |

0.4MPa~0.6MPa |

|||

|

Control |

Time/energy |

|||

|

Stroke |

30mm |

|||

|

Head size |

440*230*400mm |

|||

|

Generator |

450*435*140mm |

|||

|

Weight |

80kg |

|||

Advantages of ultrasonic metal welding

The welding material does not melt, and the metal is not fragile

The conductivity is good after welding, and the resistivity is extremely low or almost zero.

Low requirements on the surface of the weld metal, both oxidation and electroplating can be welded.

The soldering time is short, without any flux, gas, or solder.

Welding without sparks, environmental protection and safety.

Materials and Applications

Ni-MH batteries, nickel-metal hydride batteries, nickel mesh and nickel sheets welding and nickel sheets welding.

Lithium battery and polymer battery copper foil and nickel sheet welding, and aluminum foil and aluminum sheet welding.

Wires welding to each other, and the wires weld to one or multiple wires.

Wires weld with various electronic components, contacts and connectors.

Welding of large heat sinks, heat exchange fins and honeycomb

ApplicationS

Gold, silver, iron, aluminum, alloy, steel, diamond welding between the same materials or welding of different materials.

Company Advantages

Guangzhou Minder-Hightech Co.,ltd is located in guang zhou. We are a company integrating production, service and trade, with the main product of industrial machinery. Minder Machine's enterprise spirit is to be united, truth-seeking, practical and innovative. The business concept is to seek development with integrity and sci-tech. We carry out the modern enterprise management system and stick to sustainable development. We continuously provide quality products and satisfactory services for new and old customers. Our company has a strong team of professional technology and R&D personnel. We also gather a skilled management team and they work hard and are willing to make breakthrough. All that brings a better future for our company. Minder Machine insists on providing customers with reasonable solutions according to their actual needs.

You are always welcomed for inquiry.