Minder Machine Vacuum Reflow Oven

Product details of the vacuum reflow oven

Product Description

The unique function of vacuum reflow oven is well received by the customers. Our vacuum reflow oven is safe during operation. Guangzhou Minder-Hightech Co.,ltd has a very strong competitive advantage.

Product Introduction

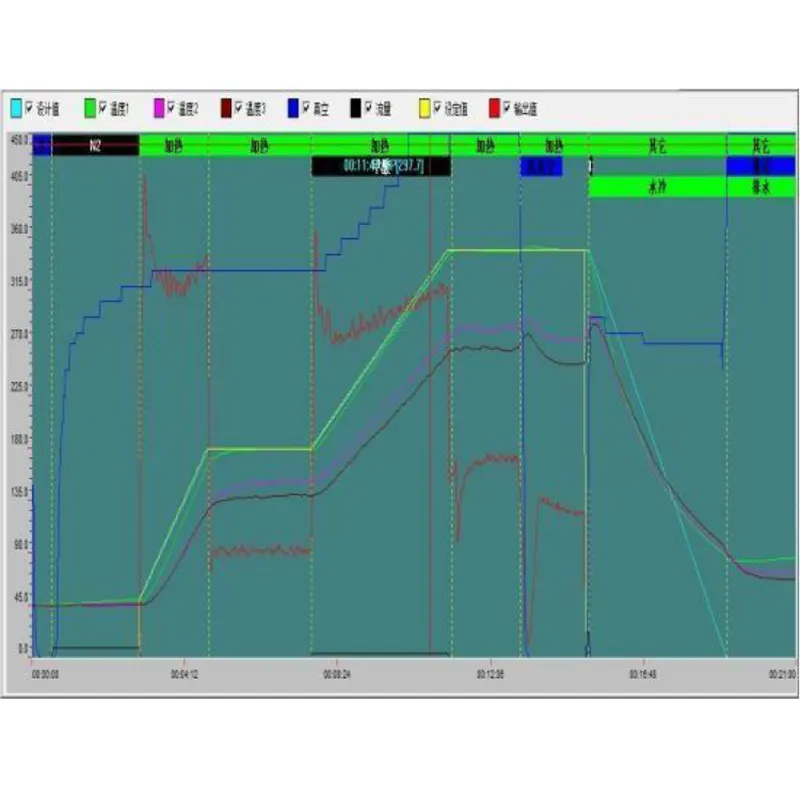

The design basis of the MDVES200 vacuum sintering furnace is vacuum and water cooling control, which can not only ensure the void rate, but also increase the cooling rate.The standard gas of MDVES200 includes: nitrogen, nitrogen-hydrogen mixed gas (95%/5%) and formic acid. The customer selects the corresponding gas as the process gas according to his actual situation, and does not need to worry about the additional configuration. The PLC control system of the equipment can well monitor the operations of vacuum pumping, inflation, heating control, and water cooling to ensure the stability of the customer's process.MUX200 is a 10L cavity, the cost performance of the product is relatively high, which can meet the needs of research and production customers.

Related Parameters

|

Structure size |

|

|

Basic frame |

820*820*1000mm |

|

cavity volume |

10L |

|

Maximum height of base |

110mm |

|

Observation window |

include |

|

Weight |

220KG |

|

Vacuum system |

|

|

Vacuum pump |

Vacuum pump with oil pollution filtering device |

|

Vacuum level |

Up to 5Pa |

|

Vacuum configuration |

1. Vacuum pump 2. Electric valve |

|

Pumping speed control |

The pumping speed of the vacuum pump can be set by the host computer software |

|

Pneumatic system |

|

|

Process gas |

N2, N2 / H2 (95% / 5%), HCOOH |

|

First gas path |

Nitrogen/nitrogen-hydrogen mixture (95%/5%) |

|

Second gas path |

HCOOH |

|

Heating and cooling system |

|

|

Heating method |

Radiant heating, contact conduction, heating rate 150℃/min |

|

Cooling method |

Contact cooling, the maximum cooling rate is 120℃/min |

|

Hot plate material |

copper alloy, thermal conductivity:≥200W/m·℃ |

|

Heating size |

240*210mm |

|

Heating device |

Heating device: the vacuum heating tube is used; the temperature is collected by the Siemens PLC module, and the PID control is controlled by the host computer Advantech. |

|

Temperature range |

Max 400℃ |

|

Power requirements |

380V, 50/60HZ three-phase, maximum 40A |

|

Control System |

Siemens PLC + IPC |

|

Equipment power |

|

|

Coolant |

Antifreeze or distilled water ≤20℃ |

|

Pressure: |

0.2~0.4Mpa |

|

coolant flow rate |

>100L/min |

|

Water tank water capacity |

≥60L |

|

Inlet water temperature |

≤20℃ |

|

Air source |

0.4MPa≤air pressure≤0.7MPa |

|

Power supply |

single-phase three-wire system 220V, 50Hz |

|

Voltage fluctuation range |

single phase 200~230V |

|

Frequency fluctuation range |

50HZ±1HZ |

|

Equipment power consumption |

about 5KW; grounding resistance≤4Ω; |

Standard configuration

|

Host system |

Including vacuum chamber,main frame, control hardware and software |

|

Nitrogen pipeline |

Nitrogen or nitrogen/hydrogen mixture can be used as process gas |

|

Formic acid pipeline |

Bringing formic acid into the process chamber via nitrogen |

|

Water cooling pipeline |

Cooling the upper cover, lower cavity and heating plate |

|

Water cooler |

Provide continuous water cooling supply to equipment |

|

Vacuum pump |

Vacuum pump system with oil mist filtration |

Operation Conditions

|

Temperature |

10~35℃ |

|

Relative humidity |

≤80% |

|

The environment around the equipment is clean and tidy, the air is clean, and there should be no dust or gas that can cause corrosion of electrical appliances and other metal surfaces or cause conduction between metals. |

|

Features

MDVES200 is a cost-effective product with a small footprint and complete functions, which can meet customer R&D and initial production use.

The standard configuration of formic acid, nitrogen and nitrogen-hydrogen gas can meet the gas demand of various products of customers, without the trouble of adding process gas pipeline for the follow-up.

Adopting water cooling control can increase the cooling rate, so that the production rate can be increased and the production can be maximized.

When the customer relates to the vacuum sealing of the tube shell, the water cooling design will highlight the advantages and avoid the air cooling caused by the tube sheet and The puncture problem of the tube shell.

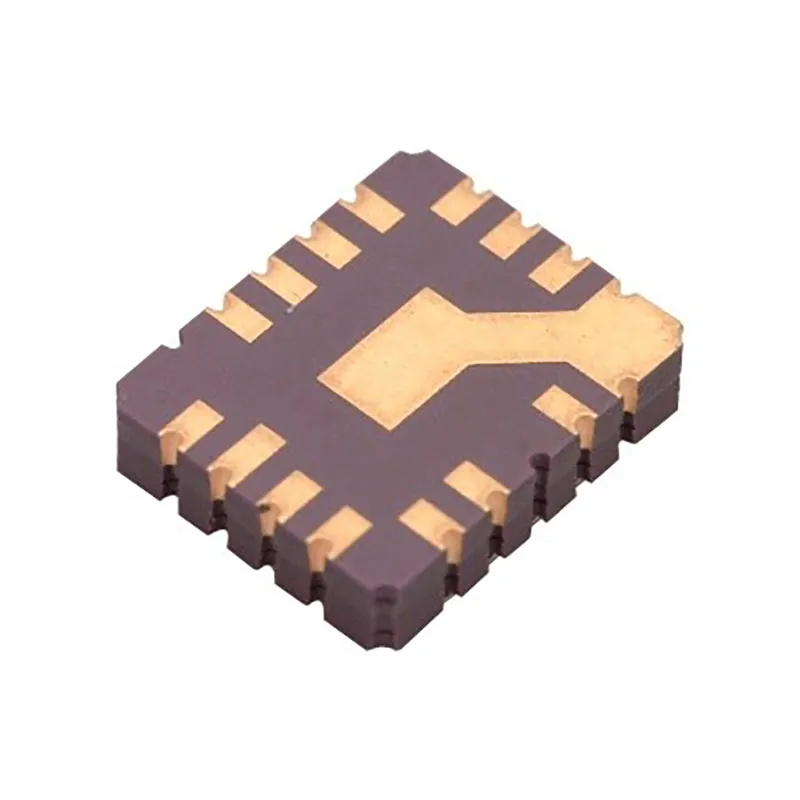

ApplicationS

IGBT modules, TR components, MCM, hybrid circuit packages, discrete device packages, sensor/MEMS packages (water-cooled), high-power device packages, optoelectronic device packages, air-tight packages (water-cooled), eutectic bump welding, etc.

Company Feature

• Minder Machine can fully explore the ability of every employee and provide considerate service for consumers with good professionalism.

• Minder Machine's products are favored by consumers at home and abroad.

• The geographical advantages and open traffic are conducive to the circulation and transportation of industrial machinery.

• Our company has a dedicated, diligent and stable senior management team, as well as a large number of core professional and technical personnel with strong execution and excellent technology. All this makes favorable conditions for our development.

Leave your contact information now, and Minder Machine has surprises for you.