Minder Machine Brand Surface Treatment Equipment Factory

Product details of the surface treatment equipment

Product Description

Minder Machine surface treatment equipment is precisely designed by our experts using the latest design concept. The strict quality control system is adopted to provide a strong guarantee for the quality of the product. The product is provided as per the precise needs of the customers in the market.

The role of plasma cleaning

The principle of plasma cleaning is mainly:

Etching on the surface of materials - physical effects

A large number of active particles in the plasma, such as a large number of ions, excited molecules, and free radicals, act on the surface of the solid sample, which not only removes the original contaminants and impurities, but also produces an etching effect to roughen the surface of the sample. Many fine pits are formed, increasing the surface ratio of the sample. Improve the wetting properties of solid surfaces.

Activation bond energy, cross-linking

The energy of the particles in the plasma is between 0-20 eV, and most of the bonds in the polymer are between 0-10 eV.

When a solid surface is used, the original chemical bond on the solid surface can be broken, and the free radicals in the plasma and these bonds

The formation of a network of crosslinked structures greatly activates surface activity.

Forming new functional groups - chemistry

If a reactive gas is introduced into the discharge gas, a complicated chemical reaction occurs on the surface of the activated material, and new functional groups such as a hydrocarbon group, an amino group, a carboxyl group, and the like are introduced, and these functional groups are all active groups, which can significantly improve the surface activity of the material.

Related Parameters

|

Parameter |

|

|

Dimension |

560×186×452mm(W×H×D) |

|

Weight |

20KG |

|

InputPower |

220V,50/60Hz |

|

Power |

700-900W(Adjustable) High power version for 50mm and 70mm spray guns |

|

High voltage frequency |

25-40KHz |

|

Working gas |

Anhydrous oil-free compressed air; optional argon, nitrogen, etc. |

|

Protection |

Overload protection, short circuit protection, open circuit protection, temperature protection |

|

Remote control |

Both local control and remote control |

|

Gun selection |

|

|

Rotary spray gun |

Processing width diameter: 50mm, optional 70, 30, 20mm |

|

Cable length |

3500mm,customizable |

|

Air pressure |

0.15MPa-0.3MPa(adjustable) |

Advantages of vacuum plasma cleaning

Plasma cleaning is an important material surface modification method and has been widely used in many fields.

And some traditional cleaning methods, such as ultrasonic cleaning, UV cleaning, etc., have the following advantages:

Low processing temperature

The processing temperature can be as low as 80 ° C - 50 ° C. Low processing temperatures ensure no thermal effects on the sample surface.

No pollution during the whole process

The plasma cleaner itself is a very environmentally friendly device that does not cause any pollution, and does not cause any pollution during the treatment process.

Stable processing effect

The treatment effect of plasma cleaning is very uniform and stable, and the effect of maintaining the sample after a long period of time is good.

Can handle samples of various shapes

For complex shaped samples, plasma cleaning can find the right solution.

Vacuum plasma cleaning allows for the cleaning of the internal position of the solid sample.

Product Details

Product principle

The structure of the plasma cleaning machine is mainly divided into three major components, namely high-voltage excitation power supply, plasma generator spray gun, and control system.

High voltage excitation power supply

The generation of plasma requires high-voltage excitation, and the atmospheric low- temperature plasma is excited by an intermediate frequency power supply at a frequency of 10-40 kHz. The high voltage is at 4-10KV. The parameters can be adjusted according to the actual conditions of the sample, and the optimal modification effect has been achieved.

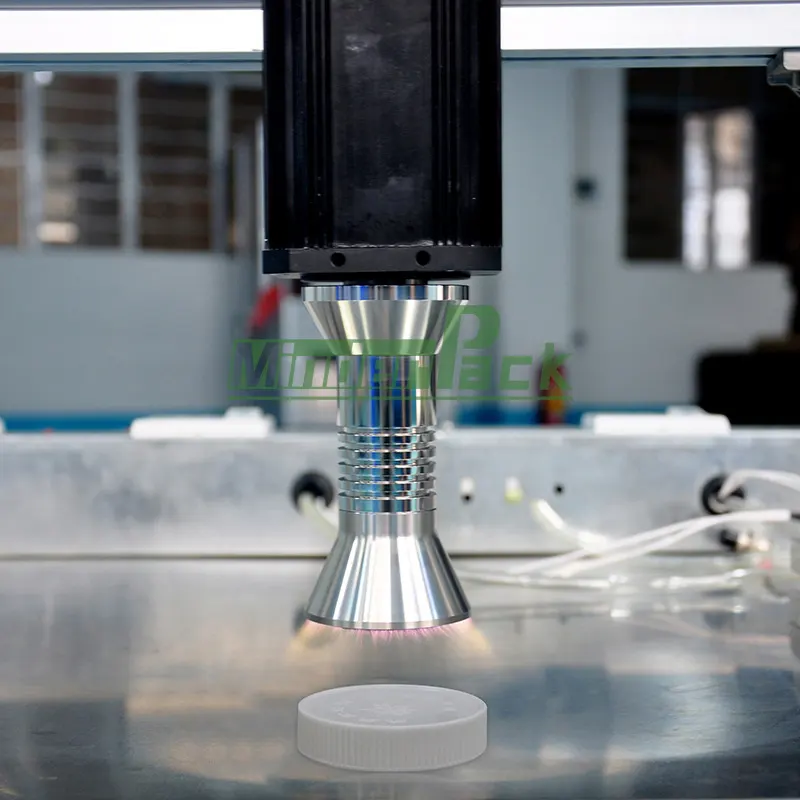

Plasma generator spray gun

The atmospheric low-temperature plasma generator spray gun can be divided into two types: jet direct injection and rotary direct injection. The difference is that the treatment area is different.

Control syste m

The control system functions to control the operation of the entire atmospheric low temperature plasma cleaning equipment and the protection of the overall system.

Performance advantage

Germancircuit technology

High-density plasma is generated using German high-voltage excitation power circuit technology to ensure superior cleaning results.

Comprehensive security protection

Temperature safety protection function, overload protection function, air pressure abnormality protection function, short circuit breaking alarm protection function, various misoperation protection functions.

Unique discharge technology

Special treatment and special structure of the discharge device ensure a stable and uniform plasma.

With asse mbly line production

According to the user's site requirements, the optimal pipeline production plan is configured to greatly improve production efficiency.

Quality product parts

All the components of the product are made of top quality parts at home and abroad to ensure

superior equipment performance.

Low temperature cleaning

Meet the temperature requirements of different occasions, no temperature impact on the cleaning products

Precision CNC machining

Imported precision CNC machine tool processing technology, and equipped with imported three- coordinate measuring instrument for quality monitoring

Company Advantage

• Minder Machine has a group of senior engineers to form a technical team. Moreover, we have many experienced production personnel. All this builds a stable foundation for vigorous development.

• Minder Machine enjoys developed telecommunication and traffic convenience. The geographic location is superior and the natural conditions are good.

• Minder Machine's products have been loved and recognized by people of many countries and have been sold well both at home and abroad.

• It has been years since our company was built in We not only have professional R&D and production capacity, but also lead the industry in terms of technology and scale.

Dear customer, if you have any questions about Minder Machine's industrial machinery, please call us. We will sincerely reply with an answer to your question and provide you with professional services.