Custom Made Vacuum Packing Machine Manufacturer Company

Product Introduction

The semi-automatic parallel seam welding machine MD-100 produced by guangzhou MinderHightech is a shell and cap sealing equipment that integrates a parallel sealing machine and a glove box. Through vacuum baking and operation of the capping process in the glove box, the moisture and oxygen content in the shell can be reduced to meet the needs of high performance and high reliability.This equipment consists of parallel sealing machine and glove box. The sealing machine completes the capping process of the tube shell, and the glove box provides a process environment with low oxygen and low water vapor content for the capping process. The parallel seam welding machine is placed in the operation box of the glove box. After the material is baked in the vacuum oven, it is transferred from the inner door of the operation box to the operation box. After the capping process is completed, it is taken out through the exchange box.

Related Parameters

|

Welding parameters |

Maximum welding power |

6KW 220V 50/60Hz |

|

Welding speed |

0.1mm/s~30mm/s |

|

|

Welding pressure |

0~1500g |

|

|

Axis of motion |

Positioning accuracy of the motion axis |

0.02mm |

|

Rotation angle range of shell |

360° |

|

|

Welding tightness |

Meets the airtightness requirements of GJB548B-2005 "Microelectronics Test Methods and Procedures" |

|

|

ØGlove box technical indicators |

||

|

Operating cabinet |

Box size |

900mm( high)x 750mm(deep)x 1200mm(long) |

|

gloves: |

8-inch glove mouth, 0.4mm thick butyl gloves, hard aluminum alloy glove mouth (after anti-corrosion treatment), caliber 220mm. Number of gloves: 2 |

|

|

Can maintain a certain positive and negative pressure during use(-12mbar-12mbar) |

||

|

Box with automatic air supplement and flushing function, PLC intelligent control pressure |

||

|

Integrated humidity detection system (dew point test) |

||

|

Integrated oxygen content detection system (oxygen sensor detection) |

||

|

Automatic cleaning function: water and oxygen parameters can be set, and the cleaning function is automatically turned on according to the setting requirements |

||

|

Oven and transition chamber |

Oven (inner) size |

300mm(high)×300mm(width)×350mm(long) |

|

Tray: |

Three-layer work partition and four-layer temperature zone heating |

|

|

The PLC can realize the intelligent control of the periodic inflation, pumping and flushing of the heating system, and the supplementary gas comes from the inside of the box |

||

|

Heating method: |

heating plate heating, 4 layers |

|

|

Temperature control range: |

150℃ |

|

|

Temperature control accuracy: |

+/-2℃ |

|

|

Uniformity of temperature distribution: the temperature distribution difference is controlled at + / 5 ℃ |

||

Features

Multiple welding modes: round welding, rectangular welding, regular polygon welding and array welding.

The advanced sealing and welding energy control scheme significantly improves the welding quality of the device edge and corner.

Accurate control of electrode wheel pressure

Very slow welding (for ceramic shell)

Cover plate pressing device.

Easy management of power parameters

Electrode wheel protection function

PKG size range(3×3)mm~(100×100)mm

KG PKG shapeSquare, round, regular polygon

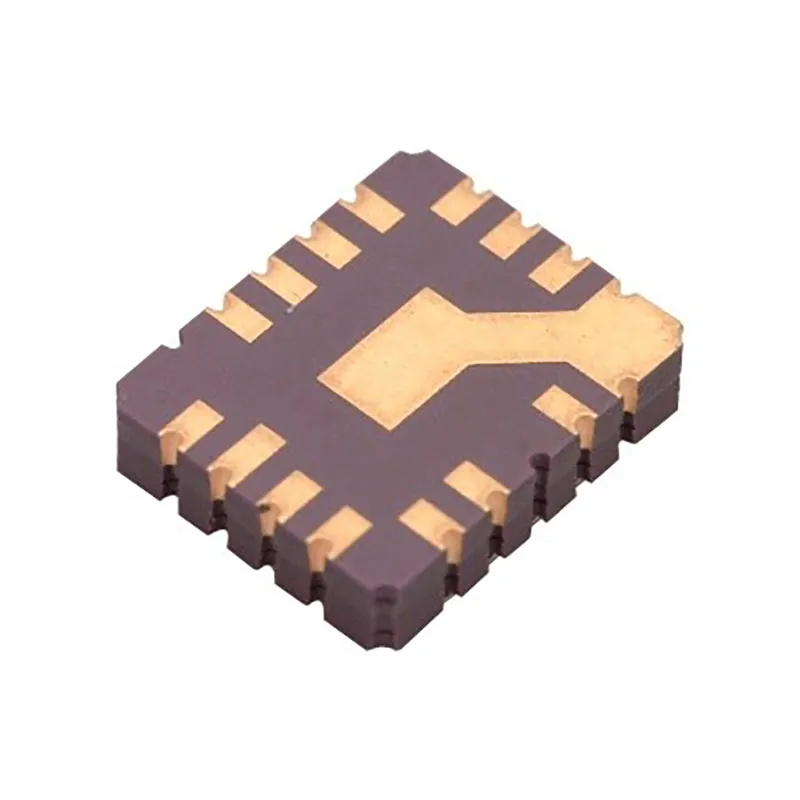

Parallel Seam Welding Machine

Company Advantages

· The quality of Minder Machine vacuum packing machine manufacturer is well-controlled. The processing of wood materials is extremely strict to meet the safety standards in the sauna industry.

· This product has required safety. It has no sharp points, edges, or potential areas for unintended squeezing/entrapment of fingers and other human appendages.

· The product is leading the market trend and has a bright market prospect.

Company Features

· With strong developing and manufacturing abilities of vacuum packing machine manufacturer, Guangzhou Minder-Hightech Co.,ltd has won an honorable reputation in the domestic market.

· We have imported the latest generation of manufacturing facilities. Having our own powerful production facilities helps us gain flexibility, as well as propose and verify the feasibility of newly developed products.

· Minder-Hightech will continue to enrich the product lines that consumers around the world would love.

Application of the Product

Minder Machine's vacuum packing machine manufacturer can be used in different fields.

With Internet technology, we provide a one-stop solution for practical and effective implementation of related problems encountered in the process of purchasing products.