Streamlining Production: Unveiling The Marvels Of Automatic Wire Bonding Machines

Welcome to our world of innovation and automation! In today's fast-paced industry, efficiency and precision are paramount, and nothing exemplifies this better than the marvels of automatic wire bonding machines. We cordially invite you to delve into the fascinating realm of streamlined production, where cutting-edge technology seamlessly interweaves with meticulous craftsmanship. In this article, we unlock the secrets behind these extraordinary machines and how they revolutionize the wire bonding process, ultimately reshaping the future of manufacturing. Prepare to be enthralled as we unravel the captivating advantages and intricacies of these game-changing devices. Join us on this riveting exploration as we unveil the immense potential and boundless possibilities that automatic wire bonding machines bring. Discover how this innovative technology propels industries forward, propelling efficiency, functionality, and reliability to unprecedented heights. Get ready to redefine your understanding of wire bonding and embark on an enlightening journey filled with insights that will leave you yearning for more.

Understanding the Basics: What is Automatic Wire Bonding?

In the fast-paced world of manufacturing, efficiency is key. Companies are constantly striving to streamline their production processes, looking for innovative solutions to maximize output while minimizing costs. One such innovation that has revolutionized the electronics industry is the automatic wire bonding machine.

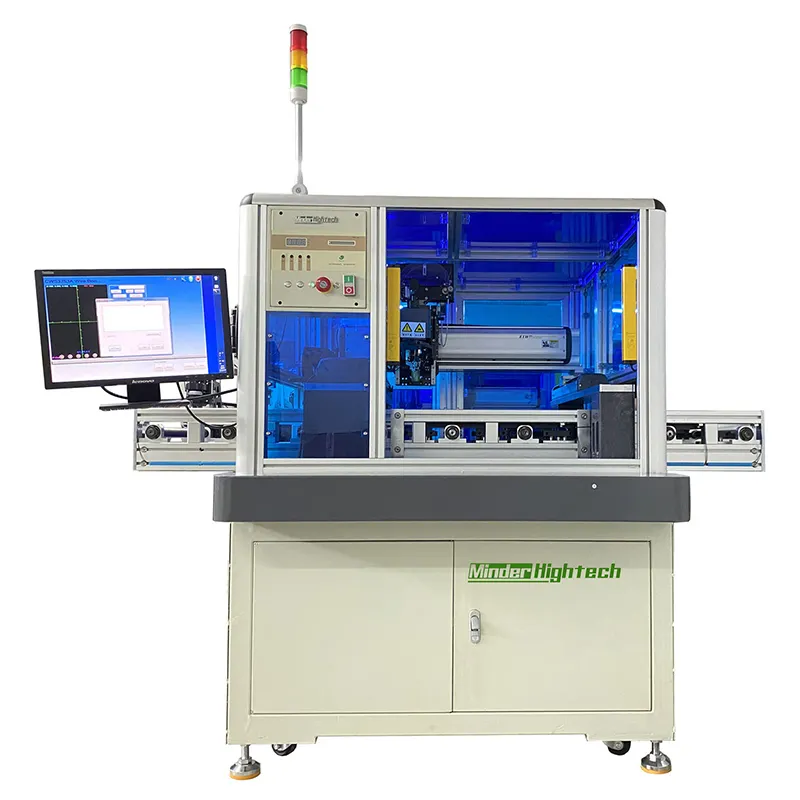

Automatic wire bonding machines, such as the one offered by Minder Machine, play a crucial role in the production of electronic devices. These machines are responsible for creating the electrical connections between the integrated circuits (ICs) and the leads of the semiconductor devices, ensuring proper functionality and reliable performance.

So, what exactly is automatic wire bonding? In simple terms, it is a process that involves connecting the electrical leads of the ICs to the corresponding leads on the semiconductor device using tiny wires. This bonding process creates a secure and reliable electrical connection, enabling the flow of electrical signals between the IC and the device.

The automatic wire bonding machine is designed to streamline this bonding process, making it faster and more efficient. The machine utilizes advanced technology and precision components to achieve precise and reliable wire bonding, ensuring the highest quality connections.

One key component of the automatic wire bonding machine is the bonder. This is the part of the machine that actually creates the wire bonds. The bonder uses ultrasonic or thermosonic bonding techniques to create the bond between the wire and the leads. Ultrasonic bonding uses high-frequency vibrations to bond the wire to the leads, while thermosonic bonding combines heat and pressure to achieve the bond.

Another important component of the automatic wire bonding machine is the wire feeder. This component is responsible for supplying the machine with the wire needed for the bonding process. The wire feeder carefully feeds the wire through the machine, ensuring that it is properly positioned and ready for bonding.

The automatic wire bonding machine also features a precision mechanism that controls the movement of the IC and the semiconductor device. This mechanism ensures that the wire is accurately positioned for bonding and allows for precise alignment of the leads.

In addition to its efficiency and precision, the automatic wire bonding machine offers several other advantages over traditional manual wire bonding. Firstly, it significantly reduces the risk of human error, ensuring consistent and reliable wire bonding. Secondly, it increases productivity by automating the bonding process, allowing for higher volumes of production. Lastly, it minimizes material waste by optimizing the use of wire, resulting in cost savings for manufacturers.

Minder Machine, a leading manufacturer of automatic wire bonding machines, has been at the forefront of this technology for years. Their machines are known for their reliability, precision, and advanced features. With a wide range of models to choose from, Minder Machine offers solutions for various applications and industries.

In conclusion, the automatic wire bonding machine is an essential tool in the electronics manufacturing industry. It plays a crucial role in creating reliable and efficient electrical connections between ICs and semiconductor devices. With its advanced technology, precision components, and automated features, the automatic wire bonding machine has revolutionized the production process, allowing for higher volumes of production, reduced costs, and improved overall quality. Minder Machine, with its reputation for excellence, is a trusted name in the industry, providing cutting-edge solutions to manufacturers worldwide.

Enhancing Efficiency: The Benefits of Implementing Automatic Wire Bonding Machines

Automatic wire bonding machines have revolutionized the manufacturing industry by streamlining production processes and significantly enhancing efficiency. In this article, we will delve into the numerous benefits that come with implementing these advanced machines and explore how they can contribute to the overall success of businesses. As a leading provider of industrial machinery, Minder Machine is at the forefront of this technological advancement, offering innovative solutions to meet the growing demand for efficiency and productivity.

One of the primary advantages of automatic wire bonding machines is their ability to handle large-scale production with ease. With their high-speed and precision capabilities, these machines can quickly and accurately bond wires onto semiconductor devices, connecting various components and ensuring optimal functionality. This results in a significant reduction in production time and enables businesses to meet tight deadlines and deliver products to market more rapidly.

Moreover, the automation provided by these machines eliminates the need for manual wire bonding, a labor-intensive and time-consuming process. By automating tasks such as wire bonding, businesses can optimize their workforce, reallocating valuable human resources to other critical areas of production. This not only increases productivity but also reduces labor costs in the long run, making automatic wire bonding machines a cost-effective investment for businesses of all sizes.

In addition to saving time and labor costs, automatic wire bonding machines offer enhanced precision and accuracy. These machines employ advanced technologies such as ultrasonic and thermosonic bonding, ensuring a reliable and consistent bond between wires and semiconductor devices. The precise control and monitoring capabilities of these machines guarantee that each bond is flawless, minimizing the risk of defective products and costly rework. This level of precision greatly improves product quality and customer satisfaction, ultimately boosting the reputation and profitability of businesses utilizing these machines.

Furthermore, automatic wire bonding machines provide a greater degree of flexibility compared to traditional manual bonding methods. They can handle a wide range of wire diameters and materials, allowing businesses to adapt to changing market demands and accommodate various product specifications. Additionally, these machines can perform complex wire bonding patterns, enabling the production of intricate and sophisticated semiconductor devices. This versatility opens up new opportunities for businesses to explore different markets and expand their product offerings, ultimately driving growth and success.

An important aspect to consider when implementing automatic wire bonding machines is the ease of integration into existing production lines. Minder Machine has designed its machines to seamlessly integrate with other manufacturing equipment, ensuring a smooth transition and minimal disruption to ongoing operations. This compatibility allows businesses to maximize their existing infrastructure and leverage the advantages of automatic wire bonding without significant investments in additional machinery or extensive reconfiguration of production lines.

In conclusion, automatic wire bonding machines offered by Minder Machine are a game-changer in the manufacturing industry. Their ability to enhance efficiency, save time and labor costs, improve precision and accuracy, provide flexibility, and seamlessly integrate into existing production lines make them an invaluable asset for businesses striving to stay ahead in today's competitive market. By embracing this advanced technology, businesses can unlock the full potential of their production processes, streamline operations, and deliver superior products that meet and exceed customer expectations.

Exploring Advanced Technology: Features and Innovations in Modern Wire Bonding Machines

In today's rapidly advancing technological landscape, where precision and efficiency are paramount, automatic wire bonding machines have emerged as indispensable tools for streamlining production processes. This article will delve into the intricate world of automatic wire bonding machines, highlighting the advanced features and innovations that render them essential for the manufacturing industry. As an industry leader, Minder Machine strives to revolutionize wire bonding technology, providing cutting-edge solutions for diverse applications. Let us uncover the marvelous capabilities of automatic wire bonding machines and understand how they have become must-have equipment in modern production facilities.

High-Speed and Precision Bonding

At the heart of automatic wire bonding machines lies their ability to perform rapid and accurate wire bonding operations. With intricate mechanisms and advanced control systems, these machines provide exceptional speed and precision when connecting wires to semiconductor devices. Minder Machine's automatic wire bonding machines, equipped with state-of-the-art linear motors and real-time monitoring systems, can achieve bonding speeds of up to 10 wires per second with utmost accuracy. Such high-speed bonding capability dramatically enhances productivity, reducing assembly cycle times while maintaining impeccable quality standards.

Multiple Wire Bonding Methods

Automatic wire bonding machines offer a range of bonding methods to accommodate various application requirements. The most common methods include ball bonding and wedge bonding. Ball bonding involves using a heated tool to bond a tiny metal sphere (ball) to the semiconductor device, creating the electrical connection. On the other hand, wedge bonding employs a wedge-shaped tool to bond the wire directly onto the device. Minder Machine's automatic wire bonding machines support both ball and wedge bonding methods, giving manufacturers greater flexibility in choosing the most suitable technique for their specific applications.

Advanced Material Handling Systems

Efficient material handling is a crucial aspect of any production process, influencing overall productivity and minimizing downtime. Automatic wire bonding machines excel in this aspect, featuring advanced material handling systems that optimize workflow efficiency. Minder Machine has integrated intelligent robotics and conveyors into its automatic wire bonding machines, allowing seamless and precise handling of wire spools, lead frames, and semiconductor devices. Additionally, the machines can be integrated within automated production lines, facilitating continuous and seamless manufacturing processes.

Intuitive Control Systems and Software

Simplicity and ease-of-use are paramount in maximizing the potential of any automated machinery. To fulfill this requirement, Minder Machine has developed intuitive control systems and software interfaces for its automatic wire bonding machines. The user-friendly graphical user interface (GUI) allows operators to set up and control the machine effortlessly, minimizing the learning curve. Advanced software algorithms enable real-time monitoring, fault detection, and preventive maintenance, ensuring optimal performance and maximizing uptime. With Minder Machine's automatic wire bonding machines, manufacturers can achieve seamless integration into their existing production systems, effectively enhancing overall efficiency.

As manufacturing processes continue to evolve, the need for high-speed and precise wire bonding machines has become imperative. Automatic wire bonding machines have revolutionized production facilities worldwide, rendering manual wire bonding methods obsolete. Minder Machine, at the forefront of cutting-edge wire bonding technology, offers state-of-the-art automatic wire bonding machines that incorporate advanced features and innovations. From high-speed and precision bonding to intuitive control systems and software, these marvels of modern engineering streamline production, propel efficiency, and ensure impeccable quality standards. Embracing the transformative capabilities of automatic wire bonding machines enables manufacturers to stay ahead in the fiercely competitive market while meeting the ever-increasing demand for impeccable craftsmanship in the digital era.

Choosing the Right Machine: Factors to Consider when Selecting an Automatic Wire Bonding System

Automatic wire bonding machines have become an indispensable tool in the manufacturing industry, streamlining production and enhancing efficiency. As technology continues to advance, companies are constantly looking for ways to stay ahead of the competition and optimize their manufacturing processes. When it comes to selecting an automatic wire bonding system, several factors need to be taken into consideration.

One of the first things to consider when choosing an automatic wire bonding machine is the specific requirements of your production line. Different industries have different bonding needs, and it's crucial to select a machine that can meet those requirements. Whether you are in the electronics industry, automotive industry, or any other industry that requires wire bonding, it's important to find a machine that is designed to handle the specific materials and dimensions of your products.

Another important factor to consider is the speed and throughput of the machine. In today's fast-paced manufacturing environment, efficiency is key. The ability to handle high volumes of wire bonding in a short period of time can significantly impact overall productivity. Look for a machine that offers high-speed capability and can handle a wide range of wire diameters to ensure maximum throughput.

Reliability and durability are crucial factors to consider when selecting an automatic wire bonding system. Look for a machine that is built with high-quality materials and is designed to withstand the rigors of continuous operation. Investing in a reliable machine can help minimize downtime and reduce maintenance costs, ultimately improving the overall efficiency of your production line.

Ease of use and operator training should also be taken into account. An automatic wire bonding machine that is easy to operate and requires minimal training can help expedite the integration process and reduce errors. Look for a machine that offers user-friendly controls and comprehensive training and support programs to ensure smooth operation.

Flexibility and adaptability are two key factors to consider when selecting an automatic wire bonding system. As technology continues to evolve, the ability to adapt to changing bonding requirements is critical for staying competitive. Look for a machine that offers a wide range of bonding options, such as wedge bonding, ball bonding, and deep access bonding, to accommodate diverse production needs.

Cost is always a consideration when making any investment. While price should not be the sole determining factor, it is important to find a balance between affordability and quality. Consider the long-term return on investment (ROI) when evaluating the cost of a wire bonding machine. Look for a machine that offers a competitive price without compromising on performance and reliability.

In conclusion, choosing the right automatic wire bonding machine is a crucial decision that can significantly impact the efficiency and productivity of your production line. Consider factors such as specific bonding requirements, speed and throughput, reliability and durability, ease of use and operator training, flexibility and adaptability, and cost when making your selection. By carefully evaluating these factors and selecting a machine that aligns with your needs, you can streamline your production process and unveil the marvels of automatic wire bonding machines.

At Minder Machine, we understand the importance of selecting the right automatic wire bonding system for your manufacturing needs. With our cutting-edge technology, superior reliability, and comprehensive support, we are committed to providing the highest quality machines to help optimize your production line. Experience the wonders of automatic wire bonding with Minder Machine and take your manufacturing process to new heights.

Maximizing Productivity: Best Practices for Streamlining Production with Automatic Wire Bonding Machines

Automatic wire bonding machines have revolutionized the manufacturing industry, providing a seamless and efficient solution for electrical interconnections. These marvels of modern technology, such as the ones manufactured by Minder Machine, have greatly enhanced productivity and streamlined production processes. In this article, we will delve into the intricacies of these machines and explore the best practices for maximizing productivity.

The automatic wire bonding machine, an essential tool in semiconductor manufacturing, allows for precise and reliable bonding of wires onto semiconductor devices. This process ensures the proper functioning and connection of various components, leading to the creation of complex electronic circuits. With the advancement in technology, automatic wire bonding machines have become indispensable in the production of integrated circuits, microchips, and other electronic devices.

Minder Machine, a renowned manufacturer in the industry, has been at the forefront of developing state-of-the-art automatic wire bonding machines. These machines are meticulously designed and manufactured to meet the exacting standards of modern production processes. With a commitment to quality and efficiency, Minder Machine has established itself as a leading name in the industry.

To ensure optimal results and maximize productivity, there are several best practices to follow when using automatic wire bonding machines. Firstly, it is crucial to select the right machine for the specific application. Minder Machine offers a wide range of models, each tailored to meet different production requirements. By choosing the right machine, manufacturers can optimize productivity, reduce downtime, and minimize costs.

Secondly, proper training and education are essential for operators to harness the full potential of automatic wire bonding machines. Minder Machine provides comprehensive training programs to equip operators with the necessary skills and knowledge. Understanding the intricacies of the machine's functionality and operation allows operators to make informed decisions and troubleshoot any issues that may arise during production.

Another critical factor in maximizing productivity with automatic wire bonding machines is preventive maintenance. Regular maintenance checks and timely servicing can prevent unexpected breakdowns and keep the machines operating at peak performance. Minder Machine offers maintenance services and support, ensuring the longevity and reliability of their machines.

Additionally, optimizing the wire bonding process itself is crucial for maximizing productivity. Factors such as wire material, wire diameter, bonding force, and bonding time all play a significant role in achieving high-quality bonds. Minder Machine's automatic wire bonding machines offer precise control over these parameters, allowing manufacturers to fine-tune the process for optimal results.

Furthermore, embracing automation and integrating advanced technologies can further streamline production processes. Minder Machine's automatic wire bonding machines feature cutting-edge automation capabilities, enabling seamless integration with other manufacturing systems. This integration reduces manual intervention, minimizes human error, and increases overall efficiency.

In conclusion, automatic wire bonding machines, such as the ones manufactured by Minder Machine, have revolutionized production processes in the manufacturing industry. By following best practices such as selecting the right machine, providing proper training, implementing preventive maintenance, optimizing the bonding process, and embracing automation, manufacturers can maximize productivity and streamline production. With a commitment to innovation and quality, Minder Machine continues to push the boundaries of automatic wire bonding technology, empowering manufacturers to achieve unparalleled efficiency and productivity in their operations.

Conclusion

1. Benefits of Automatic Wire Bonding Machines:

By streamlining the production process, automatic wire bonding machines bring numerous benefits to industries. These machines enhance efficiency by eliminating the manual labor involved in wire bonding, thus reducing errors and increasing output. Moreover, they allow for faster turnaround times, enabling businesses to meet tight deadlines and deliver products to market more quickly. By automating this essential process, industries can also save on labor costs and allocate resources to other crucial areas of production or research and development.

2. Improved Quality and Reliability:

The introduction of automatic wire bonding machines elevates the quality and reliability of products in various sectors. With precise and consistent wire bonding, these machines ensure better electrical conductivity and connection integrity, leading to a higher performance and longevity of electronic devices. The automated process reduces the risk of human error, resulting in fewer defects and failures. Manufacturers can thus enjoy improved customer satisfaction, as end-users will benefit from products that are more dependable and durable.

3. Advancements in Technology:

The marvels of automatic wire bonding machines are a testament to the advancements in technology and its impact on modern industries. These machines have revolutionized the production process, optimizing efficiency and productivity. With their sophisticated capabilities, they cater to the growing demands of industries, particularly in the electronics and semiconductor sectors. As technology continues to evolve, it is certain that automatic wire bonding machines will become even more versatile, flexible, and powerful, further enhancing production capabilities and contributing to the growth of various industries.

In conclusion, automatic wire bonding machines have emerged as an invaluable tool for streamlining production in multiple industries. By eliminating manual labor, these machines enhance efficiency, reduce errors, and boost output. They also improve the quality and reliability of products, ensuring better performance and durability. Moreover, the marvels of automatic wire bonding machines highlight the constant advancements in technology and their significant impact on industrial processes. As these machines continue to evolve and become more powerful, they will undoubtedly play a vital role in shaping the future of manufacturing, enabling industries to meet the demands of a fast-paced and competitive market.