Revolutionizing Precision Electronics: The Ultimate Guide To The Automatic Wire Bonder

Welcome to our comprehensive guide on the game-changing technology that is revolutionizing precision electronics – the Automatic Wire Bonder. In this article, we delve into the intricacies of this exceptional machine, its unparalleled capabilities, and the incredible impact it has on the world of electronics manufacturing. If you're curious about the cutting-edge advancements in wire bonding and how this groundbreaking technology is propelling the industry forward, then you've come to the right place. Join us as we unravel the secrets behind the Automatic Wire Bonder and explore the ultimate guide that will leave you inspired and eager to learn more about its transformative potential.

Understanding the Need for Precision Electronics in Today's Technological Advancements

In today's rapidly advancing technological landscape, precision electronics play a crucial role in powering innovations across various industries. From smartphones to medical devices, the demand for smaller, faster, and more reliable electronic components has never been greater. This reliance on precision electronics has led to the development of cutting-edge manufacturing processes, one of which is the automatic wire bonder. In this comprehensive guide, we will explore the importance of precision electronics, delve into the world of automatic wire bonders, and highlight the revolutionary capabilities of Minder Machine's latest offering.

The Importance of Precision Electronics:

Precision electronics refer to electronic components that are manufactured with strict adherence to quality standards, ensuring accurate and reliable performance. As technological advancements continue to push the boundaries of what is possible, the need for precision electronics becomes increasingly significant. From the aerospace and automotive industries to telecommunication and healthcare sectors, precision electronics are the backbone of countless devices and systems.

Innovation and Efficiency with Automatic Wire Bonders:

Automatic wire bonders are advanced machines used in the assembly of electronic components. These cutting-edge systems provide unparalleled precision and speed, ensuring the secure connection of delicate wires to semiconductor devices. The automation of the wire bonding process eliminates human error and allows for consistent performance, ultimately boosting efficiency and reliability.

Minder Machine's Revolutionary Solution:

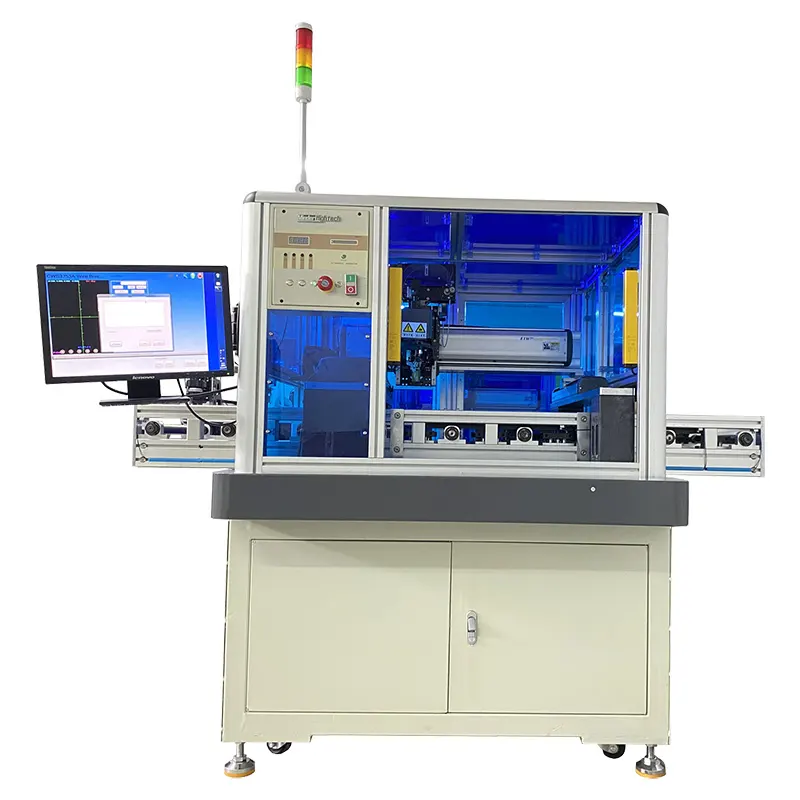

Minder Machine, a leading manufacturer in the field of precision electronics, introduces its latest breakthrough – the Minder Machine automatic wire bonder. This state-of-the-art machine is designed to revolutionize the wire bonding process, offering an unprecedented level of precision, speed, and versatility.

1. Precision:

The Minder Machine automatic wire bonder exemplifies precision engineering. Equipped with advanced optical recognition technology, it ensures accurate wire placement, resulting in reliable connections and reduced failure rates. This level of precision is crucial in industries where even the slightest error can have catastrophic consequences.

2. Speed:

In addition to precision, the Minder Machine automatic wire bonder boasts impressive speed capabilities. With its high-speed wire handling and bonding capabilities, it significantly reduces production time, enabling manufacturers to meet increasing demands without compromising quality. This accelerated production also leads to cost savings and improved overall productivity.

3. Versatility:

Minder Machine understands the diverse needs of its customers across various industries. The automatic wire bonder offers unrivaled versatility, accommodating different wire types, bonding methods, and complex geometries. This flexibility allows manufacturers to meet unique requirements and adapt to evolving technologies effortlessly.

In today's rapidly evolving technological landscape, the demand for precision electronics is at an all-time high. The automatic wire bonder has emerged as a key player in revolutionizing the manufacturing process, enabling precision, speed, and versatility like never before. Minder Machine's commitment to excellence is evident in its latest offering, providing manufacturers with a cutting-edge solution that not only meets but exceeds industry standards. With the Minder Machine automatic wire bonder, the future of precision electronics production is brighter than ever.

Demystifying Automatic Wire Bonders: How They Function and Their Key Features

In the fast-paced world of precision electronics, the use of automatic wire bonders has become indispensable. As an innovative and reliable solution, these cutting-edge machines have been revolutionizing the manufacturing process, offering unparalleled efficiency and accuracy. This comprehensive guide will delve into the details of automatic wire bonders, shedding light on their functionalities and highlighting the key features that make them essential components in the production of precision electronics.

Understanding Automatic Wire Bonders:

Automatic wire bonders, as the name suggests, are machines designed for the precise and automated bonding of wires onto electronic devices. These machines eliminate the need for manual wire bonding, reducing human error and drastically increasing productivity. At Minder Machine, we have ingeniously developed automatic wire bonders that blend advanced technology with user-friendly interfaces, making them suitable for both experienced professionals and newcomers in the industry.

Key Features of Minder Machine Automatic Wire Bonders:

1. Precision and Reliability:

Our Minder Machine automatic wire bonders utilize state-of-the-art technology, ensuring precise and reliable wire bonding with minimal inconsistencies. These machines are equipped with sophisticated sensors and motion control systems that guarantee accurate wire positioning, bond placement, and sufficient pressure to ensure a solid connection.

2. Versatility:

Minder Machine automatic wire bonders are designed to accommodate a wide range of wire bonding techniques, including ball bonding, wedge bonding, and ribbon bonding. Whether you are working with gold, aluminum, or copper wires, our machines offer the flexibility to adapt to different materials and bonding processes, making them suitable for various applications.

3. Workflow Optimization:

Efficiency is a primary focus at Minder Machine. Our automatic wire bonders are equipped with advanced software that enables seamless integration with other production processes, such as pick-and-place systems and automated testing equipment. This optimization allows for a streamlined workflow, reducing production time and increasing overall productivity.

4. User-Friendly Interface:

We understand the importance of user experience in the manufacturing industry. Minder Machine automatic wire bonders feature intuitive interfaces, allowing operators to easily set up parameters, monitor the bonding process, and make adjustments as necessary. This user-friendly design reduces training time, enhances efficiency, and minimizes the risk of errors.

5. Quality Assurance:

As a trusted brand in precision electronics, Minder Machine prioritizes quality assurance. Our automatic wire bonders perform rigorous quality checks during the bonding process, ensuring consistent and high-quality results. These machines are equipped with built-in monitoring systems that detect any deviation from set parameters, prompting immediate attention to prevent faulty bonds.

Automatic wire bonders have revolutionized the precision electronics industry, and Minder Machine stands at the forefront of this technological advancement. With their unmatched precision, versatility, workflow optimization, user-friendly interfaces, and commitment to quality assurance, Minder Machine automatic wire bonders empower manufacturers to achieve unparalleled efficiency and exceptional results. Invest in Minder Machine's automatic wire bonders and experience the future of precision electronics manufacturing today.

The Significance of Wire Bonding in Ensuring Optimal Performance and Reliability

In the world of precision electronics, wire bonding plays a vital role in ensuring optimal performance and reliability. From the smallest electronic devices to complex circuitry, wire bonding is a critical process that connects semiconductor devices to a substrate or package, enabling efficient electrical and mechanical connections. This article aims to revolutionize the understanding of wire bonding by providing the ultimate guide to the automatic wire bonder, with a specific focus on Minder Machine's cutting-edge technology.

Minder Machine, a leading manufacturer in the field of wire bonding equipment, has revolutionized the industry with its automatic wire bonders. These advanced machines have made the wire bonding process more efficient, precise, and reliable, ultimately leading to enhanced overall performance of electronic devices. By automating the wire bonding process, Minder Machine has eliminated human error and increased productivity, making it an essential tool for manufacturers worldwide.

One of the key advantages of Minder Machine's automatic wire bonder is its ability to handle a wide range of wire types and materials, including gold, aluminum, and copper. This flexibility ensures that the bonding process is optimized for each specific application, catering to various industry requirements. The machine's intelligent software system allows for quick and easy setup, reducing downtime and enhancing overall production efficiency.

Furthermore, Minder Machine's automatic wire bonders incorporate state-of-the-art technology, such as advanced bonding algorithms and real-time monitoring systems. These features ensure precise wire placement and consistent bond quality, guaranteeing optimal performance and reliability of electronic devices. With the ability to bond wires as thin as 1 mil, Minder Machine's automatic wire bonders can handle even the most delicate and intricate bonding tasks with exceptional accuracy.

The reliability of wire bonding is of utmost importance, particularly in critical applications such as aerospace, medical devices, and automotive electronics. Minder Machine's automatic wire bonders have been designed with this in mind, utilizing advanced bonding techniques and materials to create robust and durable connections. The machines are capable of achieving high bond strengths and low resistance, minimizing the risk of wire failures and ensuring long-term reliability of electronic components.

In addition to the technical aspects, Minder Machine's automatic wire bonders also prioritize user convenience and safety. The machines are equipped with user-friendly interfaces, allowing operators to easily navigate through settings and monitoring systems. Safety features, such as wire break detection and automatic shutdown mechanisms, have been integrated to prevent accidents and protect operators from potential hazards.

The implications of wire bonding in precision electronics are vast, and the significance of utilizing an automatic wire bonder cannot be emphasized enough. Minder Machine's automatic wire bonders offer unparalleled performance, reliability, and efficiency, making them an indispensable tool for manufacturers in the ever-evolving electronics industry.

In conclusion, wire bonding plays a crucial role in ensuring optimal performance and reliability in precision electronics. Minder Machine's automatic wire bonders revolutionize the industry by incorporating advanced technology and intelligent features, ultimately enhancing overall productivity and ensuring consistent bond quality. With their flexible capabilities and emphasis on user convenience and safety, Minder Machine's automatic wire bonders are the ultimate solution for manufacturers seeking to revolutionize their wire bonding processes.

Exploring the Innovative Capabilities of Automatic Wire Bonders in Revolutionizing Electronic Manufacturing Processes

Revolutionizing Precision Electronics:

The Ultimate Guide to the Automatic Wire Bonder

Subtitle: Exploring the Innovative Capabilities of Automatic Wire Bonders in Revolutionizing Electronic Manufacturing Processes

In today's fast-paced and constantly evolving world, precision electronics play a crucial role in our daily lives. From smartphones to medical devices, these sophisticated gadgets rely on intricate circuitry to function efficiently. One of the key components in the electronic manufacturing industry is the automatic wire bonder. This guide aims to delve into the revolutionary capabilities of automatic wire bonders and how they are transforming the landscape of electronic manufacturing processes.

1. Understanding the Automatic Wire Bonder:

The automatic wire bonder, also known as a wire bonding machine, is an advanced piece of equipment engineered to interconnect and secure wires on semiconductor devices. This process is vital for ensuring the functionality, reliability, and longevity of electronic components. The machine utilizes precise bonding techniques to establish connections between integrated circuit chips and bonding pads on substrates.

2. The Innovative Capabilities of Automatic Wire Bonders:

With the advancement of technology, automatic wire bonders have undergone tremendous transformation and have become increasingly sophisticated. These machines now possess innovative features that significantly enhance the overall manufacturing process. Some of these capabilities include:

a. High-Speed Bonding: Automatic wire bonders have the ability to achieve ultra-high-speed bonding, enabling manufacturers to increase productivity and meet high-volume demands efficiently.

b. Advanced Vision Systems: State-of-the-art automatic wire bonders are equipped with advanced vision systems that ensure accurate wire placement. These systems use image processing algorithms to identify bonding pads and wires, leading to higher precision and reduced error rates.

c. Multiple Wire Types: Automatic wire bonders have the capacity to work with different wire types, including gold, aluminum, and copper wires. This versatility allows manufacturers to select the optimal wire material based on specific project requirements.

d. Wire Management: These machines employ advanced wire management systems that ensure proper wire tension, alignment, and threading. This results in consistent and reliable interconnections, minimizing the risk of failures.

3. The Impact on Electronic Manufacturing Processes:

The use of automatic wire bonders in electronic manufacturing processes has brought about significant improvements, revolutionizing the industry. Some key impacts are:

a. Increased Efficiency: Automatic wire bonders enable manufacturers to streamline production workflows, reducing manual labor and human error. This increased efficiency translates into faster production times and shorter time-to-market for electronic devices.

b. Improved Quality: The precise bonding techniques and advanced vision systems of automatic wire bonders ensure reliable and consistent connections. This leads to higher-quality electronic components that meet stringent industry standards.

c. Cost Savings: By automating wire bonding processes, manufacturers can reduce costs associated with labor and minimize material waste. The enhanced productivity and accuracy provided by these machines result in significant cost savings in the long run.

d. Enhanced Reliability: The robust interconnections facilitated by automatic wire bonders contribute to the overall reliability of electronic devices. This is particularly crucial in industries such as aerospace, automotive, and medical, where failure could have severe consequences.

The advancement of automatic wire bonders has revolutionized the precision electronics industry, alleviating manufacturing challenges and providing numerous benefits. The innovative capabilities of these machines, such as high-speed bonding, advanced vision systems, and versatile wire management, have significantly improved manufacturing processes. As a leading provider of automatic wire bonding solutions, Minder Machine continues to push the boundaries of technology, delivering exceptional quality and reliability. By harnessing the power of automatic wire bonders, manufacturers can embrace the future of electronic manufacturing and stay at the forefront of innovation.

A Comprehensive Guide to Choosing the Right Automatic Wire Bonder for Your Specific Application.

In the ever-evolving world of precision electronics, the demand for efficient and reliable wire bonding solutions is paramount. As manufacturers strive to meet the increasing demands of technology, the choice of the right automatic wire bonder becomes crucial. This comprehensive guide, brought to you by Minder Machine, will delve into the intricacies of automatic wire bonders, helping you make an informed decision for your specific application.

Understanding the Automatic Wire Bonder:

Automatic wire bonders are advanced machines designed to connect wires to semiconductor devices, ensuring a reliable and long-lasting electrical connection. These wire bonders use a combination of heat, pressure, and ultrasonic energy to create a secure bond between the wire and the semiconductor component. With different types of wire bonding available, such as ball bonding and wedge bonding, it is essential to have a thorough understanding of your specific application requirements.

Factors to Consider when Choosing an Automatic Wire Bonder:

1. Bonding Technique:

The first aspect to consider is the bonding technique required for your application. Ball bonding is widely used in the semiconductor industry due to its versatility and reliability. Wedge bonding, on the other hand, offers superior mechanical strength and is suitable for applications that demand high durability. Analyzing the bonding technique needed will help streamline your choice of an automatic wire bonder.

2. Wire Type and Diameter:

The wire type and diameter play a crucial role in determining the wire bonder that suits your application. Commonly used wires include gold, copper, and aluminum. Each wire material has its own unique properties, such as conductivity and thermal expansion, which must align with your specific application requirements. Moreover, the wire diameter influences the capabilities of the wire bonder, as some machines are better equipped to handle thicker wires than others.

3. Machine Speed and Throughput:

Efficiency is a key consideration when selecting an automatic wire bonder. The speed and throughput of the machine will directly impact your production capacity. High-speed wire bonders are ideal for applications where productivity is paramount, while slower machines may be better suited for low-volume, high-precision applications. Understanding your production requirements will aid in determining the appropriate machine speed and throughput.

4. System Integration:

In today's interconnected world, it is essential to consider the compatibility and integration of the automatic wire bonder with your existing manufacturing system. Seamless communication and data exchange between machines contribute to a streamlined production process, reducing downtime and increasing productivity. Prioritize wire bonders that offer comprehensive system integration capabilities, such as compatibility with industry-standard protocols and automation interfaces.

5. Safety Features:

Safety is of utmost importance in any manufacturing environment. Selecting an automatic wire bonder that incorporates cutting-edge safety features ensures the well-being of your operators and protects your valuable equipment. Look for features such as interlock systems, safety guards, and emergency stop buttons to mitigate accidents and minimize downtime.

Choosing the right automatic wire bonder is a critical decision that directly impacts the quality, productivity, and success of your precision electronics manufacturing. By considering factors such as bonding technique, wire type and diameter, machine speed and throughput, system integration, and safety features, you can make an informed choice for your specific application. Trust in Minder Machine, a leading provider of automatic wire bonders, to revolutionize your precision electronics manufacturing process.

Conclusion

1. The importance of automatic wire bonders in the precision electronics industry.

2. The advancements and innovations in automatic wire bonding technology.

3. The benefits and advantages of using automatic wire bonders.

4. The future potential and role of automatic wire bonders in revolutionizing precision electronics.

In conclusion, the automatic wire bonder stands as a game-changer in the field of precision electronics. Its ability to seamlessly connect microchips, packages, and substrates while ensuring top-notch precision and reliability has truly revolutionized the industry. Through the advancements and innovations in automatic wire bonding technology, manufacturers are now able to achieve higher productivity and yield rates, resulting in cost-efficient and high-performance electronic devices. Not only does this technology offer significant time and cost savings, but it also allows for more compact and intricate designs, opening doors for further miniaturization and innovation. As we look to the future, the potential of automatic wire bonders remains vast, as they continue to drive advancements in precision electronics and reshape the landscape of the industry.